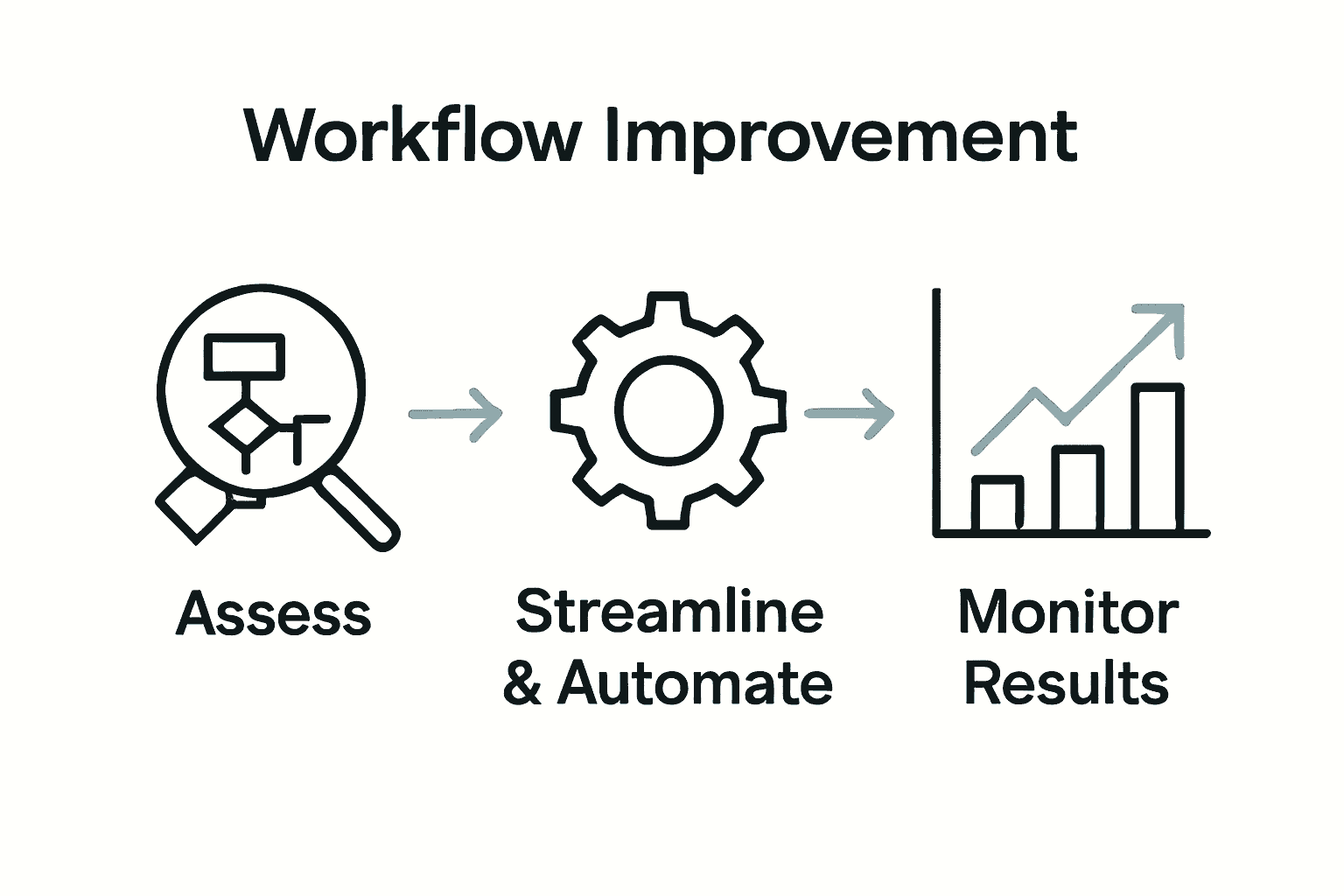

Laboratories lose up to 40 percent of their productive time due to inefficient workflows. This hidden drain slows down results and piles up costs, making lab optimization more crucial than ever. Rethinking your laboratory setup, protocols, and daily processes can spark dramatic improvements in accuracy and speed. With practical strategies rooted in research, you will discover smarter ways to assess, streamline, and elevate every aspect of your lab operations.

Table of Contents

- Step 1: Assess Current Laboratory Processes

- Step 2: Streamline Equipment and Resource Layout

- Step 3: Automate Repetitive Laboratory Tasks

- Step 4: Standardize Protocols and Documentation

- Step 5: Monitor and Verify Workflow Improvements

Quick Summary

| Key Point | Explanation |

|---|---|

| 1. Assess current laboratory processes | Document existing workflows to identify inefficiencies and bottlenecks. This is crucial for understanding areas that need improvement. |

| 2. Optimize equipment layout | Arrange equipment strategically to minimize movement and enhance workflow efficiency. This reduces time wasted and physical strain on staff. |

| 3. Automate repetitive tasks | Implement automation for tasks like data entry and specimen tracking to decrease manual errors and free up staff for more complex work. |

| 4. Standardize protocols and documentation | Develop clear Standard Operating Procedures (SOPs) to ensure consistency and facilitate training among team members. |

| 5. Monitor workflow improvements | Create a system to track key performance indicators (KPIs) and continually assess workflow changes for effectiveness and areas to optimize further. |

Step 1: Assess Current Laboratory Processes

Improving laboratory efficiency starts with a comprehensive evaluation of your existing workflows. According to a detailed study by the College of American Pathologists pubmed, workflow mapping is a critical first step in identifying potential bottlenecks and optimization opportunities across laboratory processes.

To effectively assess your current laboratory processes, begin with a systematic documentation approach. Create a detailed process map that tracks each step of your current workflow from specimen collection to final analysis. Start by walking through your laboratory and observing actual work patterns tracking time spent at each station. Note down specific activities like sample preparation, instrument setup, data recording and transfer, and analysis steps. Pay special attention to transition points where delays or inefficiencies might occur.

As you map out your processes, look for specific indicators of potential workflow interruptions. These might include redundant steps unnecessary paperwork manual data transcription waiting times for equipment or reagents and inconsistent procedural approaches among team members. Quantify these observations with precise measurements tracking time spent and resources utilized at each stage.

Remember that small improvements can compound into significant efficiency gains over time.

Remember that small improvements can compound into significant efficiency gains over time.

The goal of this assessment is not to criticize current practices but to identify strategic opportunities for streamlining and optimization. Enhance Your Lab Efficiency with Accuris Instruments can provide additional insights into modern laboratory workflow improvements. By systematically documenting and analyzing your current processes you will create a solid foundation for targeted enhancements in the subsequent steps of laboratory workflow optimization.

Step 2: Streamline Equipment and Resource Layout

Optimizing your laboratory’s physical setup is crucial for maximizing workflow efficiency. According to research from the National Society for Histotechnology nsh, strategic equipment placement and resource allocation can significantly improve overall laboratory performance.

Begin by creating a detailed spatial analysis of your current laboratory layout. Analyze the physical movement patterns of your team members and track how frequently different equipment and resources are accessed. The goal is to minimize unnecessary movement and create intuitive work zones that reduce time waste. A study on Lean management principles pubmed demonstrates that restructuring sample and staff flow can dramatically reduce turnaround times.

Consider implementing a zone-based approach to your laboratory design. Group related equipment and resources together based on frequency of use and interdependence. High traffic areas should have clear pathways and minimal obstruction. Place frequently used instruments in central locations accessible to multiple team members. Create dedicated workstations for specific processes to minimize cross contamination and optimize workflow continuity.

Careful spatial planning goes beyond mere convenience. By thoughtfully arranging your laboratory resources you can reduce physical strain on staff improve safety protocols and create a more efficient working environment. Boost Your Lab Efficiency with Benchmark Centrifuges offers additional perspectives on optimizing laboratory equipment placement. The next step involves implementing these strategic layout modifications and monitoring their impact on overall laboratory productivity.

Step 3: Automate Repetitive Laboratory Tasks

Streamlining your laboratory workflow requires strategic automation of repetitive processes. Research from the Journal of Medical Biochemistry pmc demonstrates that laboratory information systems can significantly reduce manual errors and improve overall efficiency.

Begin by identifying the most time consuming and repetitive tasks in your laboratory workflow. Common candidates for automation include data entry specimen tracking sample preparation and initial screening processes. A comprehensive review in Cureus pmc highlights how Laboratory Information Management Systems (LIMS) can transform specimen collection handling and analysis protocols. Look for software and hardware solutions that integrate seamlessly with your existing equipment and can handle multiple steps simultaneously.

When implementing automation technologies consider the following strategic approaches. Select tools that offer modular integration allowing gradual implementation without disrupting current workflows. Prioritize solutions with user friendly interfaces that require minimal additional training for your team. Create standard operating procedures that clearly outline how automated systems will interact with manual processes. Shop Genomics AutoMATE™ 96 Microplate Pipetting Workstation provides an excellent example of precision automation technology that can significantly reduce repetitive manual tasks.

Remember that successful automation is not about replacing human expertise but augmenting it. By carefully selecting and implementing automated technologies you can free your team to focus on more complex analytical tasks that require critical thinking and specialized knowledge. The next phase of your workflow optimization will involve training your team to effectively utilize these new automated systems.

Step 4: Standardize Protocols and Documentation

Creating consistent and comprehensive documentation is essential for maintaining laboratory quality and efficiency. Research published in the Archives of Pathology & Laboratory Medicine pmc emphasizes the critical role of structured processes in identifying and addressing potential quality gaps in laboratory testing.

Develop a comprehensive documentation framework that covers every aspect of your laboratory workflow. Start by creating detailed standard operating procedures (SOPs) for each critical process. These documents should provide step by step instructions that can be easily understood by all team members. Include specific details such as required equipment precise measurement techniques safety protocols and expected outcomes. Ensure that your documentation is both thorough and accessible avoiding overly complex language that might confuse team members.

Implement a robust version control system for all your protocols and documentation. This means creating a centralized digital repository where all team members can access the most recent versions of SOPs and reference materials. Establish a clear review and update process that requires periodic evaluation of existing protocols. Encourage team input and feedback to continuously refine and improve documentation. Include mechanisms for tracking changes documenting the rationale behind protocol modifications and maintaining a clear audit trail.

Remember that standardization is an ongoing process. Your documentation should be a living system that evolves with your laboratory practices technological advancements and emerging best practices. Enhance Your Laboratory Efficiency with Accuris QuadCount™ Cell can provide additional insights into effective laboratory documentation strategies. The next phase of your workflow optimization will involve training your team on these new standardized protocols and ensuring consistent implementation across all laboratory operations.

Step 5: Monitor and Verify Workflow Improvements

Verifying the effectiveness of your laboratory workflow optimization requires systematic and continuous evaluation. A comprehensive survey from the Bigpicture consortium pmc underscores the critical importance of implementing rigorous quality checks across digital laboratory workflows.

Establish a robust performance tracking system that captures key performance indicators (KPIs) for your laboratory processes. Select measurable metrics such as turnaround times error rates resource utilization and team productivity. Use statistical analysis and data visualization tools to create comprehensive dashboards that provide real time insights into your workflow performance. A case study in BMC Medical Informatics and Decision Making pmc demonstrates how continuous monitoring using the Lean method can systematically identify and address workflow inefficiencies.

Implement a structured feedback loop that involves regular team reviews and data driven assessments. Schedule monthly or quarterly comprehensive reviews where team members can discuss observed improvements challenges and potential further optimizations. Create mechanisms for capturing qualitative feedback alongside quantitative metrics. This approach ensures that your workflow improvements are not just statistically validated but also align with the practical experiences of your laboratory personnel. Enhance Your Laboratory Efficiency with Accuris QuadCount™ Cell can provide additional resources for effective performance tracking. The final stage of your workflow optimization journey involves iterative refinement based on these ongoing monitoring and verification processes.

Transform Your Laboratory Workflow for Maximum Efficiency

Struggling with bottlenecks and repetitive tasks in your laboratory workflow is a common challenge. This article highlights key steps like automating routine tasks, standardizing protocols, and optimizing equipment layout to help you reclaim valuable time and reduce errors. If you’re aiming to boost productivity while maintaining high quality, understanding these concepts is crucial.

At Shop Genomics, we understand how vital it is to have access to reliable and advanced tools that support these exact improvements. From precision automation solutions like the AutoMATE™ 96 Microplate Pipetting Workstation to cutting-edge equipment that streamlines your processes, we are your partner in laboratory innovation. Our mission is to make these technologies accessible and affordable to help you accelerate discoveries without compromise.

Ready to elevate your laboratory’s efficiency to the next level? Explore how our specialized instruments and workflow solutions can empower your team to work smarter, not harder. Visit Shop Genomics today and start transforming your lab processes for lasting success.

Frequently Asked Questions

How can I assess my laboratory’s current workflow processes?

To assess your laboratory’s current workflow processes, you need to create a detailed process map that documents each step from specimen collection to final analysis. Walk through your laboratory, observe work patterns, and track time spent at each station to identify bottlenecks and inefficiencies.

What steps should I take to optimize the layout of my laboratory?

To optimize your laboratory layout, conduct a spatial analysis of the workspace by tracking how often different equipment and resources are accessed. Rearrange equipment based on usage and create intuitive work zones to minimize unnecessary movement and enhance workflow efficiency.

What types of tasks should I consider automating in my laboratory?

Focus on automating repetitive tasks such as data entry, specimen tracking, and sample preparation to improve efficiency. Identify the most time-consuming tasks and explore technologies that can integrate smoothly into your existing workflows, potentially reducing these tasks by around 30%.

How do I create standardized protocols and documentation for my lab?

Develop a comprehensive documentation framework that includes clear standard operating procedures (SOPs) for each critical process in your lab. Ensure these documents are accessible and easy to understand to maintain consistency and quality across all laboratory operations.

What metrics should I monitor to verify the effectiveness of my workflow improvements?

Monitor key performance indicators (KPIs) such as turnaround times, error rates, and resource utilization to evaluate workflow improvements. Using data visualization tools, create dashboards that allow for real-time tracking of these metrics and facilitate data-driven assessments.

How often should I review and update my laboratory’s workflows and protocols?

Schedule regular reviews—ideally monthly or quarterly—to evaluate your workflows and protocols. This habitual reassessment allows for continuous improvements and ensures that your procedures stay relevant and efficient.