Across International

Planetary Ball Mill 4x100ml Gear-Drive 0.4L

Planetary Ball Mill 4x100ml Gear-Drive 0.4L

SKU: PQN04

- Regular price

- Price: $4,490.00

- Regular price

- List Price: $5,282.35

- Sale price

- Price: $4,490.00

- Unit price

- / per

Couldn't load pickup availability

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

Planetary Ball Mill 4x100ml Gear-Drive (0.4L)

The PQ-N04 series Planetary Ball Mill is designed for high-efficiency mixing, homogenizing, fine grinding, mechanical alloying, and colloidal grinding. With its versatile design, it caters to various applications, such as small-volume high-tech material production, cell disruption, and even for research samples. Its gear-drive mechanism offers a reliable and efficient alternative to traditional belt-driven systems, eliminating common issues like belt creep and abrasion.

Key Features:

-

High Efficiency and Low Noise:

The mill is designed for both wet and dry milling with minimal noise, making it suitable for lab environments where noise control is important. -

Four Grinding Stations:

Equipped with four grinding stations on the "Sun Wheel," the system allows simultaneous milling of four samples, each in its own grinding jar. This results in highly efficient, parallel processing of different materials or sample sizes. -

Wide Application Range:

The planetary ball mill is ideal for tasks like fine grinding, mechanical alloying, and cell disruption, especially for small-scale production or research. Vacuum jars can be used for processing samples under a vacuum environment. -

Precision Grinding:

The grinding balls inside the jars move under Coriolis Forces, which results in both frictional and impact forces acting on the samples. This generates high dynamic energies that efficiently reduce the granularity of the final product to as small as 0.1 micron. -

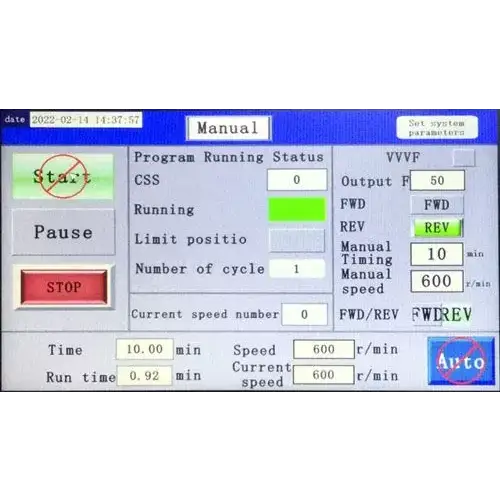

Variable Milling Methods:

The system supports different milling modes based on your needs:- Single direction without timing for continuous milling.

- Single direction with timing for a specific milling time before auto-shutdown.

- Bi-direction with timing for alternating rotation.

- Single/bi-direction with pause intervals for more complex time cycles.

-

Adjustable Operating Conditions:

You can adjust the rotation direction, speed, and time, with precise control over the operation to optimize results for each material type. -

Leak-proof Jars for Wet Grinding:

Optional leak-proof jars are available for wet grinding applications, preventing contamination and ensuring safety. -

Safety and Convenience:

- Safety switch automatically shuts down the machine if the cover is opened during operation.

- Low noise and compact design ensure smooth operation without disturbing the lab environment.

-

Customizable Grinding Jars and Balls:

Various sizes and materials of grinding jars and balls are available, allowing you to tailor the system to your specific sample types and needs.

Specifications:

-

Electrical Requirements:

110V or 220V, 50/60Hz, single phase, 370 watts. -

Capacity:

0.4L (can hold up to 4 jars of 50ml to 100ml each). -

Compatible Jars:

- Non-vacuum jars: 50ml - 100ml (x4).

- Vacuum jars: 50ml (x4).

-

Feeding Granularity:

- Soil materials ≤ 10mm.

- Other materials ≤ 3mm (preliminary size reduction may be required for larger samples).

-

Discharging Granularity:

Down to 0.1 micron. -

Maximum Continuous Operating Time:

72 hours. -

Rotation Speed:

Planetary jar rotation speed: 350 rpm. -

Dimensions:

- Unit dimensions: 24 x 14 x 17.5 inches (DxWxH).

- Height with cover open: 32 inches.

-

Shipping Dimensions:

27 x 17 x 23 inches (LxWxH). -

Weight:

Shipping weight: 170 lbs. -

Compliance:

CE certified.

Grinding Ball and Jar Size Options:

| Model | Capacity | Max Rotation Speed | Power | Dimensions (mm) |

|---|---|---|---|---|

| PQN04 | 0.4L | 600 rpm | 0.37KW | 360 x 575 x 470 |

| PQN1 | 1L | 580 rpm | 0.75KW | 460 x 760 x 600 |

| PQN2 | 2L | 580 rpm | 0.75KW | 460 x 760 x 600 |

| PQN4 | 4L | 530 rpm | 1.5KW | 460 x 760 x 680 |

| PQN8 | 8L | 440 rpm | 4KW | 1080 x 640 x 750 |

| PQN12 | 12L | 440 rpm | 4KW | 1080 x 640 x 750 |

| PQN16 | 16L | 270 rpm | 5.5KW | 1130 x 720 x 810 |

| PQN20 | 20L | 270 rpm | 5.5KW | 1130 x 720 x 810 |

Applications:

- Material Production: Ideal for small-scale high-tech material production and research samples.

- Fine Grinding: Used for producing materials with high uniformity and fine granularity down to sub-micron levels.

- Mechanical Alloying: Useful for alloying metals at the research level or in production environments.

- Colloidal Grinding: Effective in grinding materials into fine colloids for various laboratory applications.

Conclusion:

The PQ-N04 Planetary Ball Mill offers an efficient, flexible solution for grinding and mixing a wide range of materials at the laboratory scale. Its gear-drive mechanism ensures smooth, reliable operation with low maintenance, while its ability to process multiple samples simultaneously boosts productivity. The mill's versatility in grinding methods and the use of vacuum jars makes it ideal for various research and industrial applications.