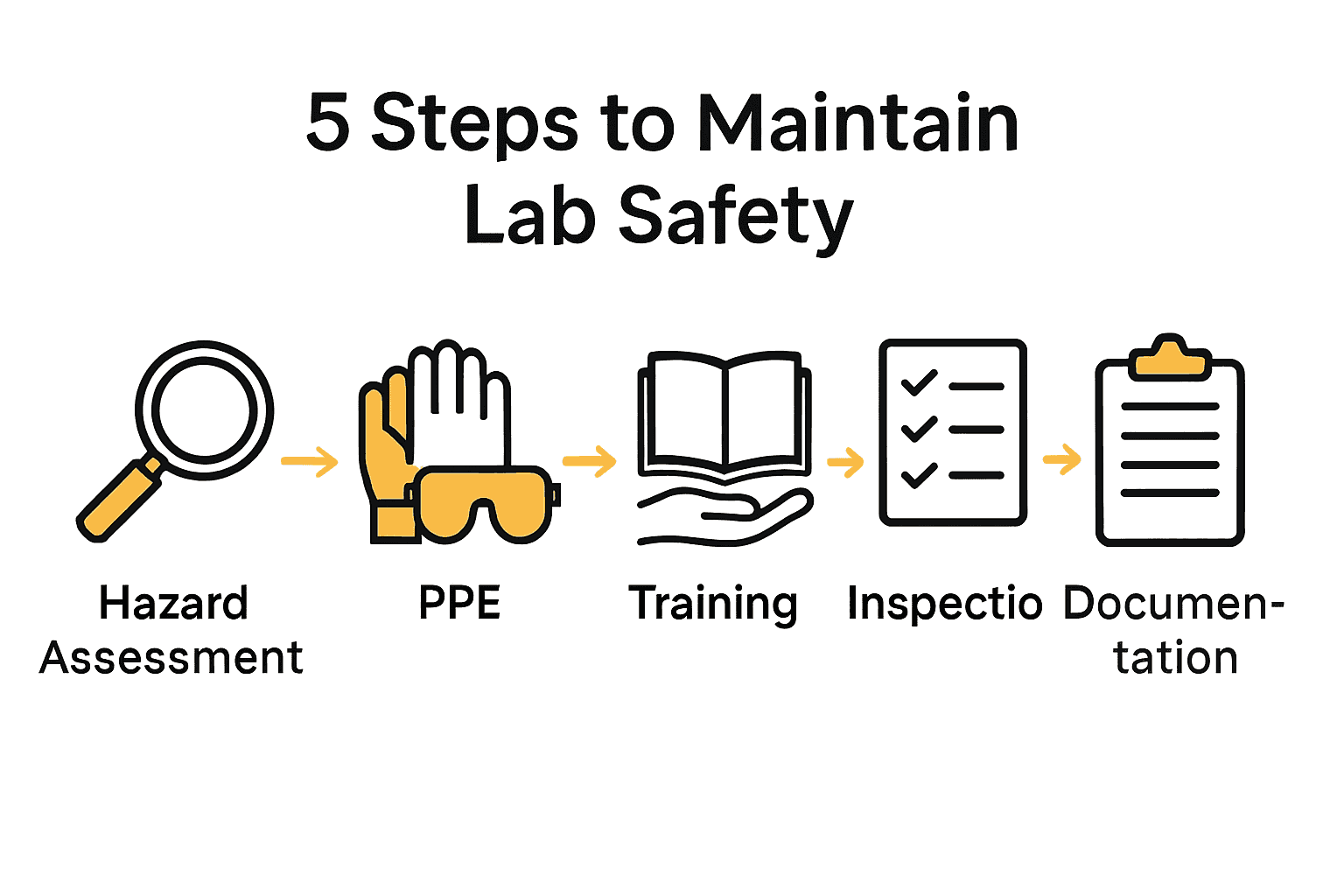

Lab accidents are more common than many realize, with nearly 40% of researchers reporting at least one injury during their careers. Maintaining safety in a laboratory is more than following checklists—it is a core responsibility that protects both people and research outcomes. By following proven steps for hazard assessment, equipment protocols, training, monitoring, and documentation, you create a solid foundation for safer, more efficient science every day.

Table of Contents

- Step 1: Assess Potential Hazards Before Starting Work

- Step 2: Implement Proper Safety Equipment and Protocols

- Step 3: Educate and Train All Laboratory Personnel

- Step 4: Monitor Safety Adherence Through Regular Inspections

- Step 5: Document Incidents and Update Safety Measures

Quick Summary

| Key Point | Explanation |

|---|---|

| 1. Conduct a comprehensive hazard assessment | Before starting any work, identify potential risks in your lab environment to ensure safety. |

| 2. Implement appropriate PPE and protocols | Use tailored personal protective equipment and establish clear safety procedures. |

| 3. Train lab personnel thoroughly | Provide structured safety training and hands-on demonstrations for all team members. |

| 4. Monitor safety adherence regularly | Conduct scheduled inspections to ensure compliance with safety protocols and spot areas for improvement. |

| 5. Document incidents meticulously | Create a transparent incident reporting system to analyze risks and improve safety measures continuously. |

Step 1: Assess potential hazards before starting work

Before diving into your laboratory work, you need to systematically identify and evaluate potential risks that could compromise your safety and research integrity. This critical first step involves a comprehensive scan of your workspace, equipment, and planned experimental procedures to prevent accidents and protect yourself and your colleagues.

Start by conducting a thorough walkthrough of your laboratory environment. Look closely at each workstation, scanning for potential chemical, biological, electrical, and physical hazards. Carefully examine your equipment for signs of wear, potential malfunction, or improper setup. Review your experimental protocol and make a detailed list of all materials you will be using what potential risks they might present. Pay special attention to chemical compatibility, potential reaction dangers, required personal protective equipment (PPE), and specific handling requirements for each substance.

Pro Tip: Create a standardized hazard assessment checklist that you can use consistently across different research projects to ensure comprehensive risk evaluation.

Remember that hazard assessment is not a one time task but an ongoing process. As your experiment evolves or you introduce new materials, continuously re evaluate potential risks. This proactive approach transforms safety from a compliance requirement into an integral part of your scientific workflow.

Step 2: Implement proper safety equipment and protocols

With your potential hazards assessed, the next crucial step is implementing robust safety equipment and protocols that will protect you and your research environment. This involves strategically selecting and correctly using personal protective equipment (PPE) and establishing clear safety procedures that minimize risks during laboratory operations.

Start by selecting appropriate protective gear tailored to your specific research activities. This means choosing laboratory coveralls that provide full body coverage, chemical resistant gloves that match the substances you are handling, and safety glasses or face shields that offer comprehensive eye protection. Ensure all PPE fits properly and is in excellent condition without any tears or wear. Beyond personal equipment, establish strict access protocols for your laboratory. Restrict entry to authorized personnel only and maintain laboratory doors closed to prevent unauthorized access and potential contamination.

Pro Tip: Conduct monthly equipment inspections to verify that all safety gear remains in optimal condition and replace any items showing signs of deterioration.

[Learn more in our guide on 7 Essential Laboratory Safety Tips 2025 for comprehensive safety strategies]. Always remember that safety protocols are not static documents but living guidelines that must evolve with your research practices and technological advancements.

Step 3: Educate and train all laboratory personnel

Transforming safety awareness into actionable knowledge requires a comprehensive training approach that goes beyond simple instruction manuals. Your goal is to create a culture of safety where every team member understands not just the what and how of laboratory protocols, but the critical importance of maintaining a secure research environment.

Begin with a structured onboarding process for all new personnel that includes comprehensive safety orientation. This means providing detailed walkthroughs of equipment usage, emergency response procedures, and specific safety protocols unique to your laboratory. Develop interactive training sessions that combine theoretical knowledge with practical demonstrations. Ensure that each team member demonstrates proficiency in handling equipment, wearing personal protective gear, and responding to potential emergency scenarios. Focus on creating muscle memory for safety procedures through hands on practice and scenario based learning.

Pro Tip: Implement quarterly safety refresher courses and maintain detailed training records to track each personnel member’s safety competency.

[Explore our guide on Laboratory Workflow Optimization to enhance your team’s overall performance and safety awareness]. Remember that education is an ongoing process. Continuous learning and periodic skill assessments are the foundations of a truly safe and effective research environment.

Step 4: Monitor safety adherence through regular inspections

Ensuring laboratory safety is an ongoing process that requires systematic and consistent monitoring of your team’s adherence to established safety protocols. Your goal is to create a proactive environment where safety checks become a natural and integral part of daily research operations, preventing potential incidents before they can occur.

Develop a comprehensive inspection schedule that covers multiple dimensions of laboratory safety. This means conducting both announced and unannounced safety audits that evaluate everything from personal protective equipment usage to proper chemical storage and equipment maintenance. Create a detailed checklist that allows you to systematically assess each critical safety aspect. During inspections, observe team members performing their regular tasks, looking for both compliance with safety protocols and potential areas where additional training might be needed. Document your findings meticulously, tracking patterns and improvements over time.

Pro Tip: Use digital tracking tools to create a transparent and consistent safety inspection process that allows for real time reporting and immediate corrective actions.

Learn more about maintaining optimal [Laboratory Workflow Optimization to support your safety monitoring efforts]. Remember that effective safety monitoring is not about finding fault but about continuous improvement and creating a culture of collective responsibility.

Step 5: Document incidents and update safety measures

Documenting laboratory incidents is more than a bureaucratic requirement it is a critical mechanism for preventing future accidents and continuously improving your research environment. Your primary goal is to create a transparent reporting system that encourages open communication and transforms every potential safety challenge into an opportunity for systematic improvement.

Establish a comprehensive incident reporting protocol that captures every detail of safety events both major and minor. This means creating a standardized digital or physical form that requires detailed documentation including date time location personnel involved precise description of the incident immediate actions taken and potential root causes. Encourage a non punitive reporting culture where team members feel safe sharing information without fear of blame. Analyze these reports systematically looking for patterns potential systemic risks and opportunities to modify existing safety protocols. Each documented incident becomes a valuable data point that can help prevent future similar occurrences.

Pro Tip: Implement a confidential near miss reporting system that allows personnel to document potential safety risks before they result in actual incidents.

[Explore our guide on Safe DNA Testing in High School Labs to understand comprehensive safety documentation practices]. Remember that effective safety management is an evolving process where each documented incident represents a stepping stone toward creating a more secure and resilient research environment.

Strengthen Lab Safety with Trusted Equipment and Expert Support

Maintaining lab safety means tackling challenges like hazard assessment, proper PPE use, and ongoing safety training. When your research depends on rigorous safety protocols, having reliable and up-to-date equipment is essential to protect your team and achieve consistent results. At Shop Genomics, we understand the pressure of preventing incidents and fostering a culture of safety through quality gear and accessible technology.

Take control of your laboratory safety today by exploring our full range of advanced research tools. Whether you need durable protective gear, efficient workflow solutions, or expert guidance on maintaining compliance, we offer everything designed to empower your safety efforts. Don’t wait for preventable accidents update your lab with trusted equipment from Shop Genomics and move forward confidently. Visit Shop Genomics now to discover how we can support your safest research environment.

Frequently Asked Questions

How can I assess potential hazards in my laboratory?

Assess potential hazards by conducting a thorough walkthrough of your laboratory environment. Examine workstations, equipment, and experimental protocols to identify chemical, biological, electrical, and physical risks.

What personal protective equipment (PPE) should I implement for lab safety?

Select appropriate PPE based on your specific research activities, including chemical-resistant gloves, safety glasses, and lab coveralls. Ensure all PPE fits properly and is in excellent condition to effectively protect against hazards.

How often should I train laboratory personnel on safety protocols?

Train laboratory personnel with a comprehensive onboarding process and implement quarterly refresher courses. Regular education helps maintain high safety awareness and ensures everyone can respond effectively to emergencies.

What steps should I take for monitoring safety adherence in the lab?

Develop a comprehensive inspection schedule that includes both announced and unannounced safety audits. Use a detailed checklist to evaluate compliance regularly, and document findings to track improvements over time.

How do I document incidents and update safety measures effectively?

Establish a standardized incident reporting protocol to capture all safety events in detail. Encourage open communication about incidents and analyze reports to identify patterns and areas for improvement in your safety protocols.

How can I promote a culture of safety in my lab?

Promote a culture of safety by providing continuous education and encouraging team discussions about safety practices. Implement non-punitive incident reporting to make everyone feel comfortable sharing concerns and contributing to a safer environment.