Across International

1-Zone 1200°C 50mm OD Split Tube Furnace with Quartz Tube

1-Zone 1200°C 50mm OD Split Tube Furnace with Quartz Tube

SKU: STF1200.50.600

- Regular price

- Price: $3,590.00

- Regular price

- List Price: $4,223.53

- Sale price

- Price: $3,590.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

1200°C PE/CVD Furnace with RF Generator, Gas Mix & Pumping System (STF1200 Series)

The STF1200 series is a Chemical Vapor Deposition (CVD) and Plasma-Enhanced Chemical Vapor Deposition (PECVD) furnace system, designed for advanced material processing with precise temperature control, enhanced by a RF generator, gas mixing system, and pumping system. This furnace provides efficient solutions for creating thin films, coatings, and other materials that require precise atmospheric and temperature conditions.

Key Features:

-

Compact and Portable Design:

- The furnace is designed to be compact and mobile, making it easy to integrate into various laboratory and production environments.

-

Advanced Heating and Insulation:

- The Kanthal® (Sweden) A1 2.0 resistance coil wire heating elements are embedded in Mitsubishi® (Japan) 1500-grade fiber alumina insulation, offering excellent thermal efficiency.

- The dual-layer steel housing minimizes heat loss to the exterior while ensuring durability.

-

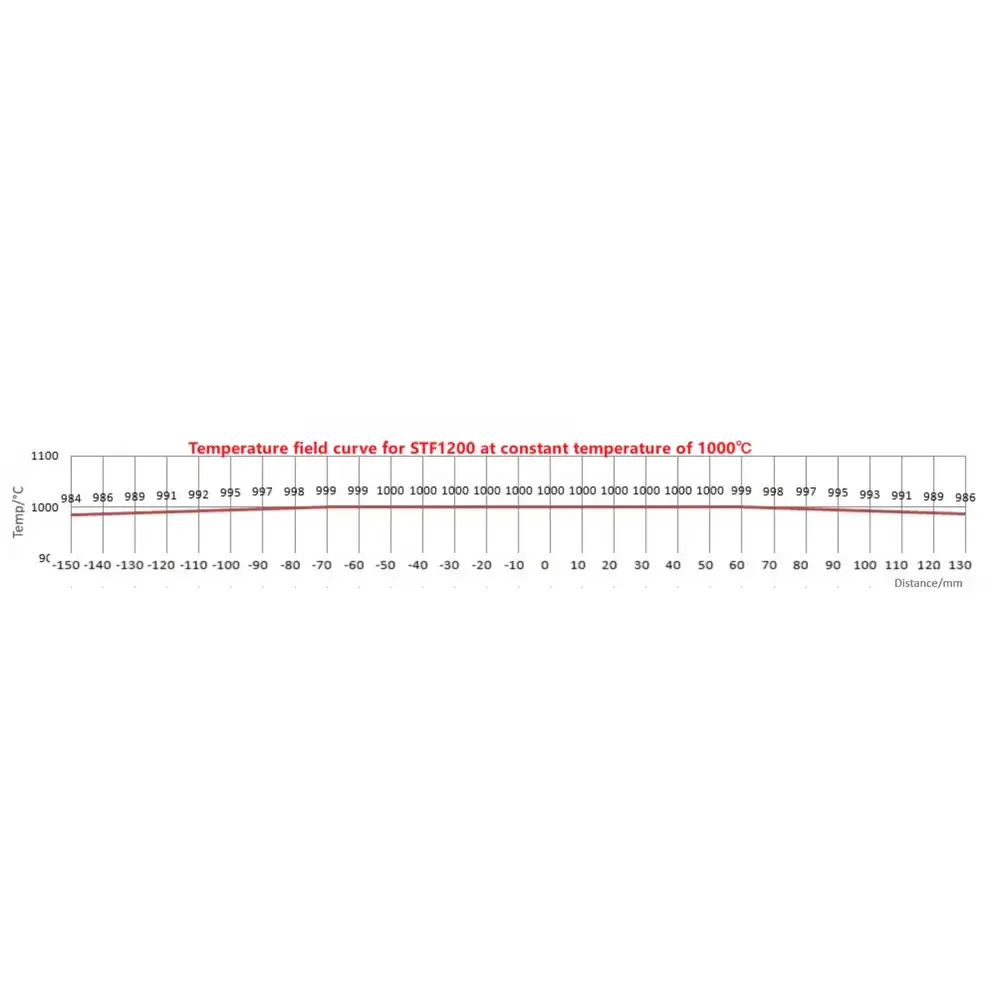

Efficient Temperature Control:

- The furnace is controlled by a Eurotherm® (UK) digital controller that provides precise PID microprocessor-based self-tuning for optimal temperature control with minimal overshoot.

- Temperature range: Max. 1200°C and constant working temperature of 1100°C.

- Thermocouple type: Type K for reliable and accurate temperature measurement.

- Heating rate: Less than 30°C/min, suitable for rapid temperature adjustments.

-

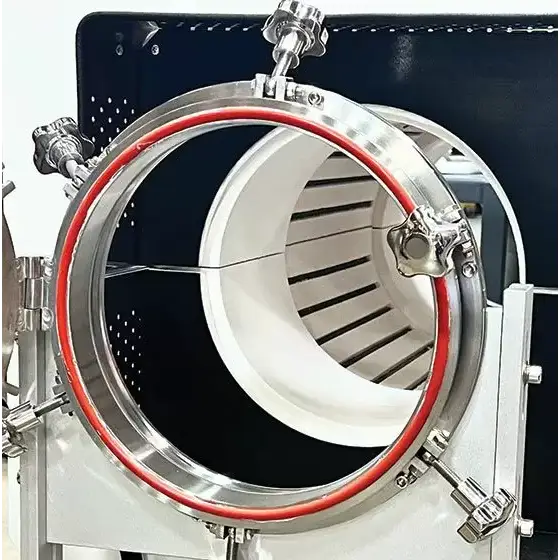

Atmospheric Control and Gas Flow:

- The furnace includes stainless steel vacuum sealing flanges with valves, a vacuum gauge, and four thermal ceramic blocks to manage gas flow.

- Multiple atmosphere processes can be handled in a single cycle, such as binder burn-out in air and parts sintering under vacuum or inert gas environments.

-

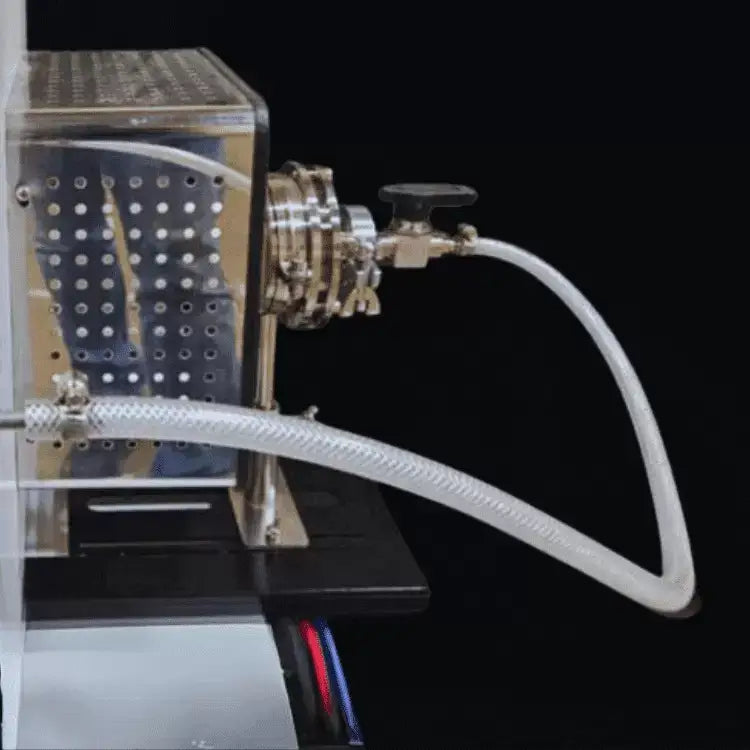

Vacuum and Pumping System:

- The vacuum pump is available for purchase, and a vacuum mobile cart can be added when the pump and digital vacuum controller are purchased together.

- The system ensures that the furnace chamber maintains the required vacuum level during operation.

-

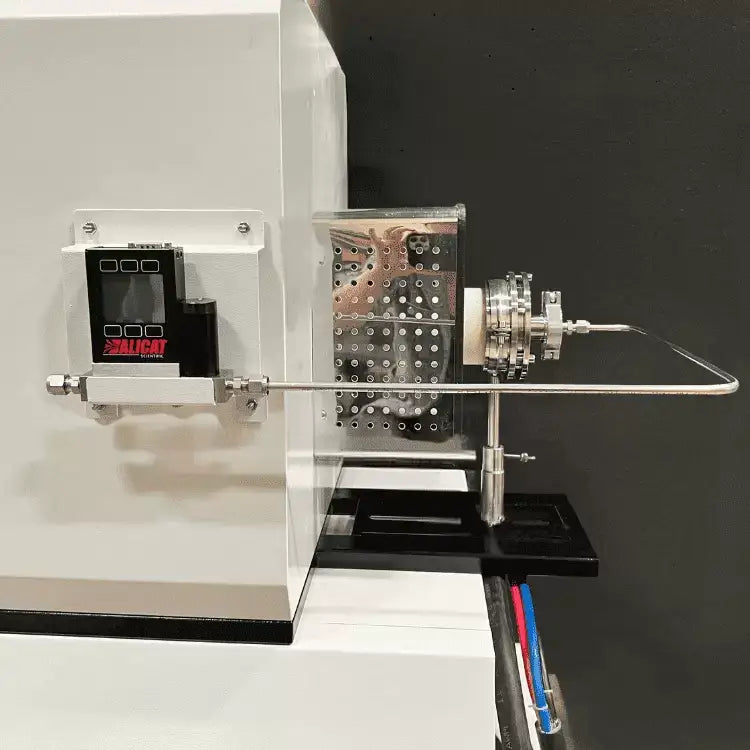

High-Frequency RF Generator for PECVD:

- The RF generator operates with 13 MHz frequency with excellent stability (±0.005%).

- The generator provides an adjustable output power range from 5 to 500 watts, allowing precise control of the plasma deposition process.

- Automatic matching ensures optimal performance by adjusting for impedance changes during operation.

- The RF output port is 50 Ω, N-type, female, suitable for connecting RF cables.

-

Computer Interface and Monitoring:

- The system has a built-in computer interface for remote control and monitoring, allowing users to connect the furnace to a PC.

- The Eurotherm® controller enables users to save and export test results for further analysis or record-keeping.

-

Safety and Protection:

- Overheat protection automatically shuts down the furnace if the temperature exceeds the acceptable range or if there’s a thermocouple failure.

- Power failure protection ensures that the furnace resumes operation from the point where it was interrupted once power is restored.

- Warning: The furnace should never be filled with explosive gases such as Hydrogen, Carbon Monoxide, or Methane, which could pose significant safety risks.

Specifications:

Furnace:

- Tube Material: Quartz

- Heating Element: Kanthal® A1 2.0 resistance coil wire

- Refractory Lining: Mitsubishi® 1500-grade fiber alumina

-

Temperature Range:

- Max Working Temperature: 1200°C

- Constant Working Temperature: 1100°C

- Thermocouple: Type K

-

Temperature Control:

- PID Controller (Eurotherm® UK)

- Temperature Control Precision: ±1°C (±1.8°F)

- Heating Rate: < 30°C/min

Vacuum Pump and Sealing System:

- Vacuum Sealing Flanges: Stainless steel flanges with valves and a vacuum gauge for sealing and gas management.

- Vacuum Gauge: Included to monitor the internal chamber pressure.

- Vacuum Mobile Cart: Available with the purchase of a vacuum pump and digital vacuum controller.

Electrical Requirements:

- Furnace Electrical: 208-240V, 50/60Hz, single-phase

- RF Generator Electrical: 208-240V, 50/60Hz

- RF Output Power: Adjustable from 5 to 500 watts (in ±1% steps)

- RF Frequency: 13 MHz with ±0.005% stability

- Reflection Power: 200 watts max

- RF Output Port: 50 Ω, N-type female

Safety Features:

- Overheat Protection: Automatic shut down when exceeding the temperature range or thermocouple failure.

- Power Failure Protection: Furnace resumes operation after power restoration.

- Warning: Hazardous gases (e.g., Hydrogen, CO, Methane) must not be used.

Applications:

The STF1200 series CVD/PECVD Furnace is ideal for:

- Thin Film Deposition: Used in semiconductor manufacturing, coatings, and materials processing.

- Plasma Treatment: Enhancing surface properties, etching, and other plasma-based processes.

- Advanced Research: Suitable for research in material science, especially when precise atmospheric and temperature conditions are required for thin film production or plasma-enhanced processes.