Across International

1200°C Controlled Atmosphere Muffle Furnace ETL/CE Certified (12x8x8)

1200°C Controlled Atmosphere Muffle Furnace ETL/CE Certified (12x8x8)

SKU: GCF1200.12.8.8

- Regular price

- Price: $7,990.00

- Regular price

- List Price: $9,400.00

- Sale price

- Price: $7,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

1200°C Controlled Atmosphere Muffle Furnace (GCF1200 Series)

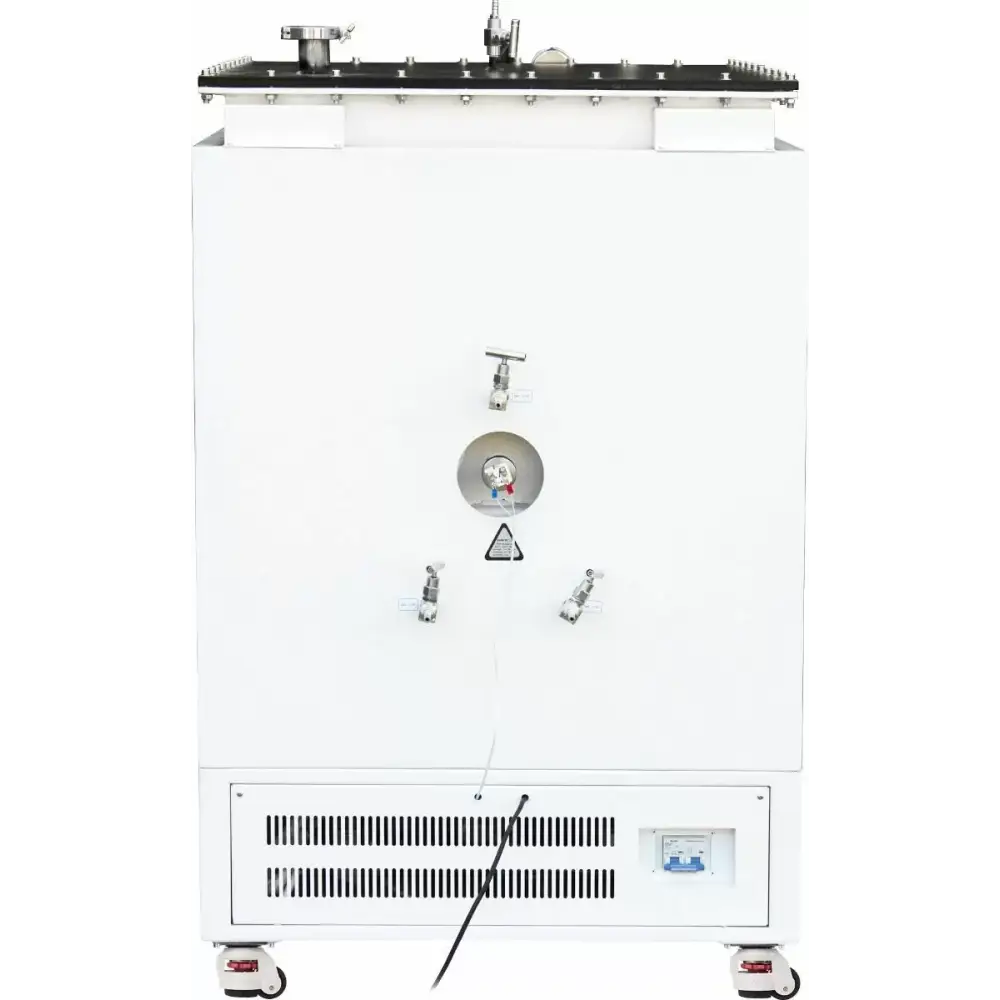

The GCF1200 series controlled atmosphere muffle furnaces are designed to offer precise temperature control and the ability to work in specific atmospheres, ideal for applications requiring exact temperatures and controlled environments. These furnaces are equipped with Kanthal A1 heating elements and Mitsubishi polycrystalline alumina fiber insulation, ensuring reliable performance even in the most demanding settings.

Key Features:

-

Controlled Atmosphere:

- Multiple gas inlets and outlets with stainless steel ball valves and flow meters to control inbound and outbound gas flows. These outlets can be ignited to burn off gases as needed.

- The furnace chamber is welded and oil leak tested to ensure complete air-tightness, essential for maintaining an accurate atmosphere inside.

- A vacuum port (KF40) is included for pre-vacuuming the chamber, which is particularly useful when using inert or protective gases.

- Gases that can be used include air, N2, Ar, NO2, CO, CO2, He, Ne, and rough vacuum, with hydrogen up to 5%.

-

Temperature Control:

- The furnace is controlled by either an Eurotherm 3204 controller (UK) or Shimaden FP93 controller (Japan). Both options provide precise temperature management and come with the ability to program ramp and dwelling cycles.

- PID self-tuning microprocessor control optimizes the thermal process with minimal temperature overshoot.

- Type K thermocouple for accurate temperature measurement, ensuring ±1°C precision.

-

Gas Atmosphere and Safety:

- The gas inlet/outlet is fitted with 1/4" hose barb and BSPT threads to easily connect to the appropriate gas supply system.

- The furnace features an overheat protection system that shuts down the unit if temperatures exceed the acceptable range or if the thermocouple fails.

- Power failure protection ensures that the furnace resumes operation once power is restored, avoiding disruptions in the process.

-

Built-in Monitoring and Control:

- Ammeter and dual voltmeters are integrated for real-time monitoring and troubleshooting.

- Computer interface allows remote control and monitoring via a PC, and users can save or export test results for analysis or documentation.

-

Atmosphere Options:

- The furnace supports multiple atmosphere processes in a single cycle. For example, binder burnout in air and sintering under a vacuum or inert gas can be done within one continuous process.

Specifications:

-

Electrical Requirements:

- 208-240V, 50/60Hz, single-phase.

-

Temperature Range:

- Max temperature: 1200°C (2192°F).

- Max constant temperature: 1100°C (2012°F).

- Min temperature: Ambient.

-

Heating Element:

- Kanthal A1 2.0 resistance coil wire from Sweden, known for durability and high heat resistance.

-

Furnace Chamber:

- Mitsubishi high-quality 1500-grade polycrystalline alumina fiber insulation for optimal heat retention and energy efficiency.

-

Temperature Controller:

- Eurotherm 3204 Controller (UK) or Shimaden FP93 (Japan), with up to 40 segments for precise temperature cycling.

- PID control ensures precise and efficient thermal management.

-

Gas and Vacuum Management:

- Gas inlet/outlet for proper gas flow control.

- Vacuum port for pre-vacuuming, with a maximum vacuum level around 100 Pa for optimal gas environment creation.

- Positive pressure should not exceed 0.02 MPa / 150 torr / 3 psi.

-

Safety:

- Overheat protection and power failure recovery.

-

Compliance:

- ETL tested to UL and CSA standards (standard).

- CE certification.

-

Warranty:

- 1-year warranty.

Size Comparison:

| Model | Chamber Size (DxWxH) | Usable Chamber Space (DxWxH) | Chamber Capacity (cu ft) | Maximum Output (kW) | Furnace Dimensions (LxWxH) | Shipping Dimensions (LxWxH) | Net Weight (Lb) | Shipping Weight (Lb) |

|---|---|---|---|---|---|---|---|---|

| GCF1200-12x8x8 | 12x8x8" | 10x7x7" | 0.44 | 4 kW | 25.6x29.5x39.4" | 38x26x44" | 350 | 420 |

| GCF1200-16x12x12 | 16x12x12" | 14x11x11" | 1.33 | 9 kW | 27.6x33.5x46.5" | 40x30x48" | 400 | 470 |

| GCF1200-20x16x16 | 20x16x16" | 18x15x15" | 2.96 | 15 kW | 33.5x40x51" | 49x44x61" | 800 | 950 |

| GCF1200-20x20x20 | 20x20x20" | 18.5x18.5x18.5" | 4.23 | 18 kW | 38x41x51" | 48x44x65" | 1000 | 1322 |

Applications:

The GCF1200 series controlled atmosphere muffle furnace is perfect for:

- Material Processing: Sintering, heat treatment, and other high-temperature applications requiring precise atmosphere control.

- Laboratory Work: For research and experiments where specific environmental conditions are crucial.

- Metal and Ceramic Processing: Sintering and treatment of metals, ceramics, and composites in controlled atmospheres, including vacuum and inert gases.