Across International

1400°C Controlled Atmosphere Muffle Furnace ETL/CE Certified 16X12X12

1400°C Controlled Atmosphere Muffle Furnace ETL/CE Certified 16X12X12

SKU: GCF1400.16.12.12

- Regular price

- Price: $17,990.00

- Regular price

- List Price: $21,164.71

- Sale price

- Price: $17,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

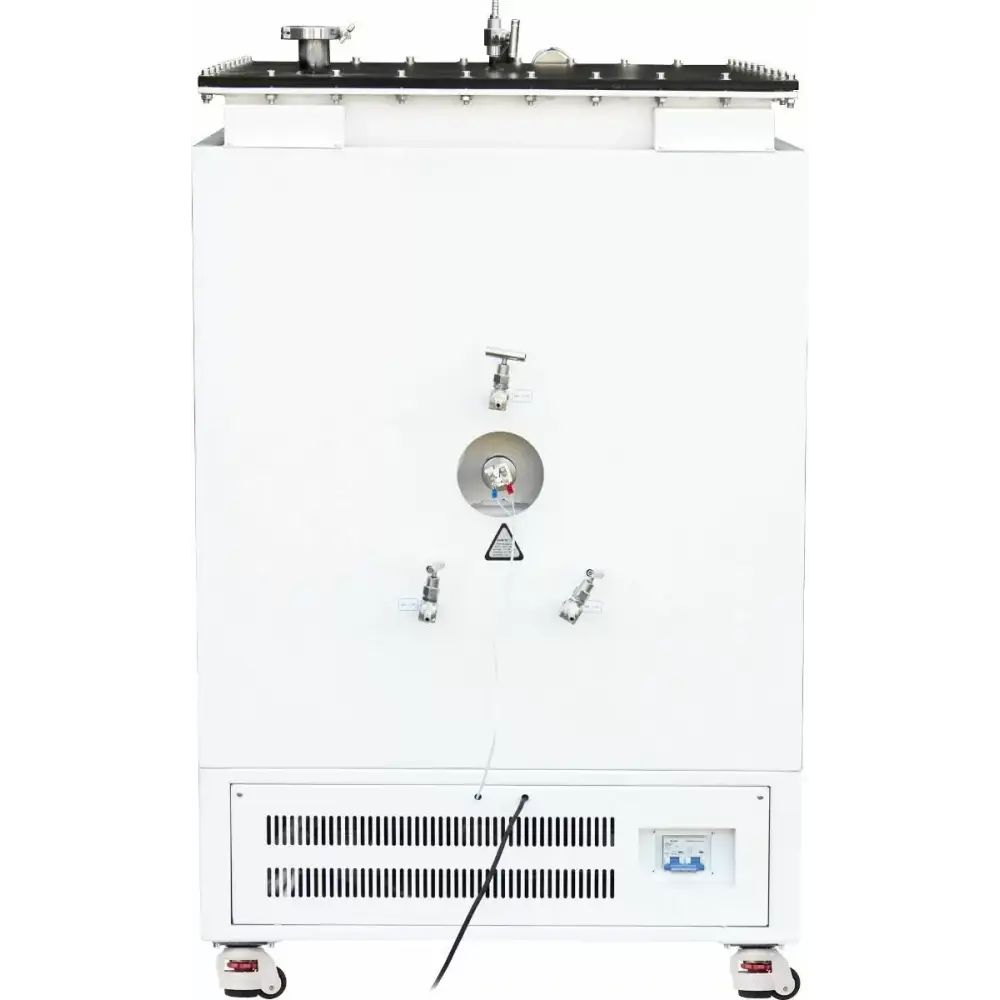

GCF1400 Controlled Atmosphere Muffle Furnace

The GCF1400 series muffle furnaces are designed for high-precision temperature control in controlled atmospheres, capable of reaching temperatures up to 1400°C. These furnaces are ideal for applications requiring exact atmospheric conditions, such as sintering, materials testing, or chemical processes, offering precise temperature control with minimal error.

Key Features:

-

High-Quality Construction:

- The furnace uses Mitsubishi (Japan) high-quality 1600-grade polycrystalline alumina fiber for the chamber insulation, ensuring high thermal efficiency and durability.

- Silicon Carbide (SiC) heating elements provide excellent performance at high temperatures, ensuring even heat distribution.

-

Controlled Atmosphere:

- The furnace features multiple gas inlets and outlets with stainless steel ball valves and a flow meter to control the inbound and outbound gas flows.

- Gas mixtures (e.g., Nitrogen, Argon, Hydrogen up to 5%, CO2) can be carefully controlled within the furnace for specialized applications like binder burnout, sintering, or material treatment.

- The furnace chamber is welded and oil leak-tested to ensure airtight sealing, with a high-temperature silicon gasket around the door for a secure seal.

- Alicat mass flow controllers are available as options for precise gas flow management (sold separately).

-

Advanced Temperature Control:

- Eurotherm 3204 (UK) or Shimaden FP93 (Japan) multi-segment digital controllers provide precise, programmable temperature control.

- Self-tuning PID control for optimum thermal process management and minimal temperature overshoot.

- Temperature accuracy: ±1°C (±1.8°F).

- The furnace is equipped with a long-life type S thermocouple for accurate temperature readings at high temperatures.

-

Vacuum and Pressure Control:

- The furnace supports rough vacuum down to 1000 Pa (hose barb connection), though it is primarily designed to be used with controlled atmospheric gases, not as a vacuum furnace.

- The furnace also features positive pressure control, with a maximum pressure of 0.02 MPa (150 torr).

-

Safety Features:

- Overheat protection automatically shuts down the furnace if the temperature exceeds the safe limit or if the thermocouple fails.

- Power failure protection ensures that the furnace will resume operation once power is restored, preserving the integrity of the process.

- Built-in ammeter and dual voltmeters for monitoring and troubleshooting the electrical system.

-

Temperature Profiles:

- Supports up to 50-segment programming with options for multiple atmosphere processes in a single cycle, such as binder burnout in air and sintering in inert gas or vacuum.

-

Cooling System:

- Built-in stainless steel water-cooling panel helps protect the furnace door’s sealing gasket during prolonged use or high-heat operations.

Specifications:

-

Chamber Dimensions:

- Available in multiple sizes:

- 6x6x6 inches (0.13 cu ft)

- 12x8x8 inches (0.44 cu ft)

- 16x12x12 inches (1.33 cu ft)

- 20x16x16 inches (2.96 cu ft)

- 20x20x20 inches (4.63 cu ft)

- Available in multiple sizes:

-

Maximum Working Temperatures:

- Air, Helium (He), Neon (Ne), Argon (Ar): 1400°C

- Nitrogen (N2): 1270°C

- Hydrocarbon gases: 1250°C

- Hydrogen (H2) up to 5%: 1200°C

- Rough vacuum: 1200°C

-

Heating Elements:

Silicon Carbide (SiC) heating elements are installed, providing efficient heating with a maximum output of:- 3 kW for smaller models (6x6x6, 12x8x8)

- 7 kW for medium models (16x12x12)

- 13 kW for larger models (20x16x16, 20x20x20)

-

Electrical Requirements:

- 208-240V, 50/60Hz, single-phase for smaller models.

- 480V, 50/60Hz, 3-phase for larger models.

-

Temperature Control System:

- Eurotherm 3204 Controller (8 segments) or Shimaden FP93 (up to 40 segments) with precise ramp and dwell programming.

-

Certification:

- ETL tested to UL and CSA standards (optional).

- CE certified (standard).

Size Comparison and Weight:

-

Smaller Models (6x6x6, 12x8x8, 16x12x12):

- Unit Dimensions: 23x28x35 inches to 31x33x44 inches

- Shipping Dimensions: 28x33x45 inches to 43x46x81 inches

- Unit/Shipping Weight: 290/400 lb to 590/720 lb

-

Larger Models (20x16x16, 20x20x20):

- Unit Dimensions: 36x40x73 inches to 40x44x77 inches

- Shipping Dimensions: 43x46x81 inches to 48x51x68 inches

- Unit/Shipping Weight: 1100/1452 lb to 1320/1672 lb

Applications:

-

Laboratory Use:

Ideal for applications requiring precise control over both temperature and atmosphere, such as sintering, ceramic firing, heat treatment of metals, or research processes. -

Industrial and Manufacturing:

Used in industries where controlled atmospheres are essential, such as in the production of high-performance materials, metal alloys, and advanced ceramics.

Warranty:

- 1-year warranty, covering parts and labor (excluding heating elements).