Across International

1700°C Max Controlled Atmosphere Muffle Furnace 6X6X6

1700°C Max Controlled Atmosphere Muffle Furnace 6X6X6

SKU: GCF1700.6.6.6

- Regular price

- Price: $16,990.00

- Regular price

- List Price: $19,988.24

- Sale price

- Price: $16,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

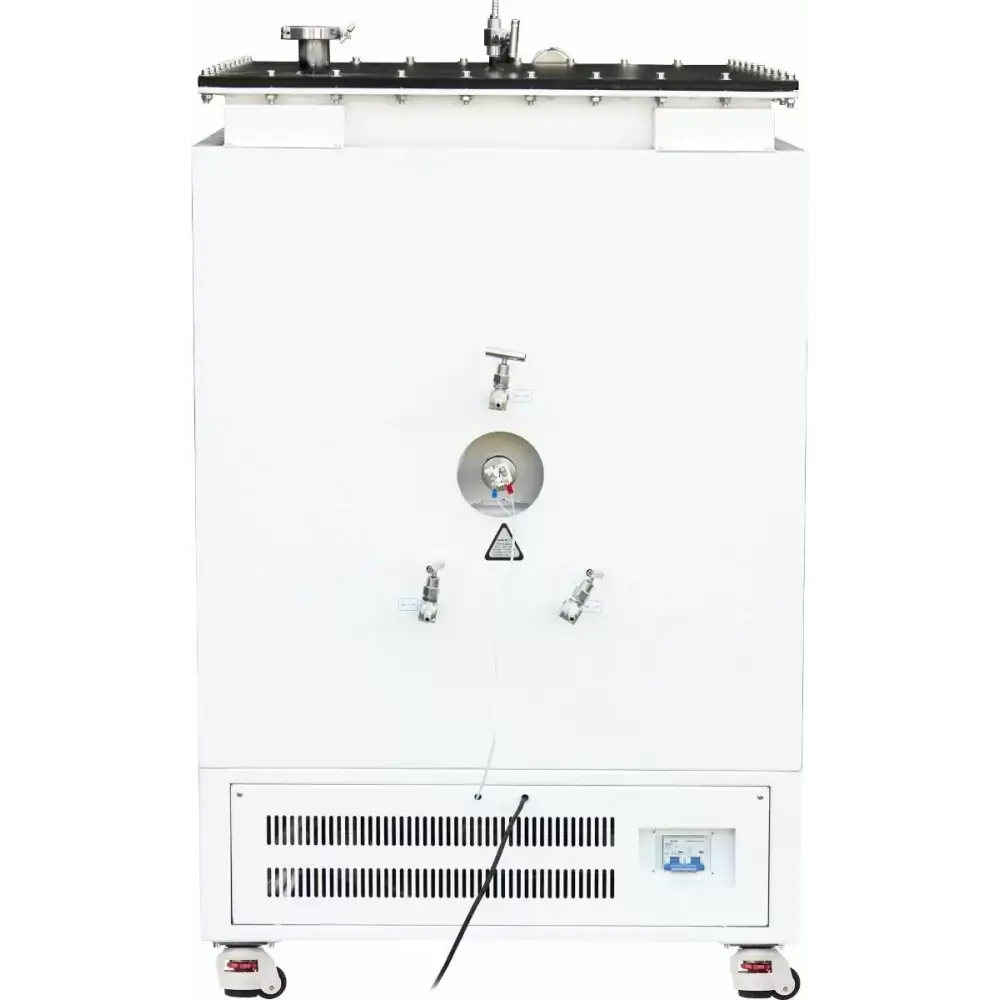

GCF1700 Controlled Atmosphere Muffle Furnace (1700°C Max)

The GCF1700 series controlled atmosphere muffle furnaces are engineered to provide precise control of temperature and atmospheric conditions for demanding high-temperature processes. Capable of reaching 1700°C, these furnaces are ideal for a variety of laboratory, industrial, and research applications that require a controlled environment with high thermal efficiency.

Key Features:

-

High-Quality Construction:

- Mitsubishi (Japan) high-grade 1800 Morgan polycrystalline alumina fiber is used for the furnace cavity, ensuring superior insulation and energy efficiency.

- The furnace uses Molybdenum Silicide (MoSi2) heating elements, which provide excellent thermal stability and high-temperature resistance.

- The furnace features a double-walled steel internal housing to minimize heat loss and improve efficiency.

-

Advanced Temperature Control:

- Eurotherm 3204 (UK) or Shimaden FP93 (Japan) multi-segment controllers, offering up to 50 segments of ramp and dwell programming, are available to provide precise temperature control.

- The furnace also includes built-in digital communications ports and USB adaptors, allowing remote control and monitoring via PC. Test results can be saved or exported for further analysis.

- The temperature control system offers ±1°C precision, ensuring consistent results.

-

Controlled Atmosphere:

- The furnace supports a variety of gases, including air, Nitrogen (N2), Argon (Ar), CO2, He, Ne, and Hydrogen (H2) up to 5%.

- The gas inlet/outlet features 1/4" hose barb with BSPT threads for easy integration with external gas flow systems.

- Multiple gas inlets and outlets are fitted with stainless steel ball valves and flow meters to control gas flow in and out of the furnace.

- The furnace chamber is welded and oil-leak tested to ensure airtight sealing, with a high-temperature silicon gasket sealing the door.

-

Vacuum and Pressure Control:

- The furnace features a KF40 vacuum port for rough vacuum operations (down to 1000 Pa with hose barb connections, 100 Pa with flange connections).

- Positive pressure is maintained at a maximum of 0.02 MPa (150 torr / 3 psi).

-

Safety Features:

- Overheat protection ensures the furnace shuts down if the temperature exceeds the set limit or if the thermocouple fails.

- Power failure protection allows the furnace to resume operations once power is restored, ensuring the consistency of the process.

- Built-in ammeter and dual voltmeters for monitoring electrical parameters.

-

Cooling System:

- A stainless steel water-cooling panel protects the furnace door’s sealing gasket during intense use, ensuring reliable operation even under high temperatures.

-

Temperature Profiles:

- The furnace supports multiple atmosphere processes in a single cycle, such as binder burnout in air and sintering under inert gas or rough vacuum conditions.

-

Compliance and Warranty:

- The furnace is CE compliant and can be ETL tested to UL and CSA standards (optional).

- 1-year warranty covers parts and labor (excluding heating elements).

Specifications:

-

Chamber Dimensions and Capacity:

- 6x6x6 inches (0.13 cu ft)

- 12x8x8 inches (0.44 cu ft)

- 16x12x12 inches (1.33 cu ft)

- 20x16x16 inches (2.96 cu ft)

- 20x20x20 inches (4.63 cu ft)

-

Heating Element:

- Molybdenum Silicide (MoSi2) heating elements provide excellent high-temperature resistance.

-

Temperature Control:

- Eurotherm 3204 (UK) or Shimaden FP93 (Japan) controllers with up to 50-segment programming.

- Precision: ±1°C.

- Maximum Heating Rate: 15°C/min.

-

Maximum Working Temperatures:

- Air: 1700°C

- Helium (He), Neon (Ne), Argon (Ar): 1650°C

- Nitrogen (N2): 1500°C

- Hydrocarbon Gas: 1550°C

- Hydrogen (H2, up to 5%): 1500°C

- Rough Vacuum: 1400°C

-

Electrical Requirements:

- 208-240V, 50/60Hz, single-phase for smaller models.

- 220V, three-phase for 20x16x16 model.

- 480V, two-phase for the larger 20x20x20 model.

-

Size and Weight:

-

Smaller Models (6x6x6, 12x8x8, 16x12x12):

- Unit Dimensions: 30x24x45" to 34x29x60"

- Unit/Shipping Weight: 430/510 lb to 880/1050 lb

-

Larger Models (20x16x16, 20x20x20):

- Unit Dimensions: 90x100x184 cm to 100x110x195 cm

- Unit/Shipping Weight: 735/830 lb to 800/900 lb

-

Smaller Models (6x6x6, 12x8x8, 16x12x12):

Applications:

The GCF1700 is suitable for a wide range of applications:

- Laboratory Research: Ideal for materials research, sintering, ceramic production, and high-temperature treatments.

- Industrial Manufacturing: Used in the production of advanced materials, alloys, and ceramics.

- Heat Treatment: Perfect for processes requiring precise temperature control in controlled atmospheres.

Conclusion:

The GCF1700 Controlled Atmosphere Muffle Furnace provides superior performance for high-temperature applications, offering accurate control, robust construction, and excellent gas flow management. Whether for laboratory, industrial, or research use, this furnace meets the demanding needs of precision and reliability at temperatures up to 1700°C.