Across International

1750°C Max Controlled Atmosphere Muffle Furnace w/ PC Interface 20X16X16

1750°C Max Controlled Atmosphere Muffle Furnace w/ PC Interface 20X16X16

SKU: GCF1750.20.16.16

- Regular price

- Price: $44,990.00

- Regular price

- List Price: $52,929.41

- Sale price

- Price: $44,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

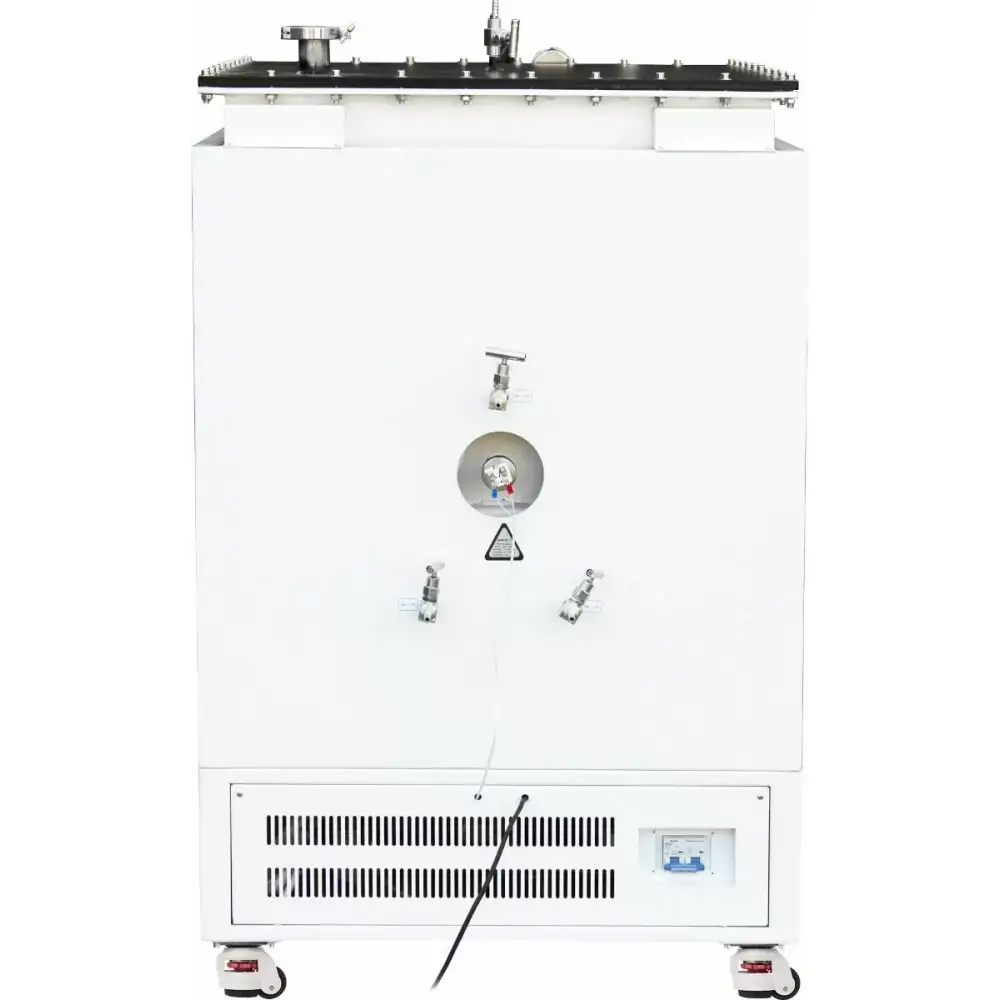

GCF1750 Controlled Atmosphere Muffle Furnace (1750°C Max)

The GCF1750 series controlled atmosphere furnaces are designed for applications that require high-temperature processes with precise control over the atmosphere. These furnaces can reach up to 1750°C, making them ideal for research, industrial, and laboratory environments where exacting conditions are needed for materials processing, sintering, and other heat treatment applications.

Key Features:

-

Superior Construction:

- The furnace chamber is built with Mitsubishi (Japan) high-quality 1800 Morgan polycrystalline alumina fiber, offering excellent insulation and heat retention.

- Molybdenum Silicide (MoSi2) heating elements are used for their ability to withstand high temperatures and provide reliable heating performance.

- A double-walled steel internal housing reduces heat loss and enhances energy efficiency.

-

Advanced Temperature Control:

- Eurotherm 3204 (UK) or Shimaden FP93 (Japan) controllers provide precise temperature regulation with up to 50 segments for ramping and dwelling, ensuring accurate thermal processes.

- These furnaces feature built-in digital communication ports and USB adaptors for remote control via PC, allowing users to monitor the furnace and export test results easily.

- Temperature control precision is within ±1°C, ensuring consistency in every cycle.

- Maximum heating rate of 15°C/min allows for rapid thermal cycling when needed.

-

Controlled Atmosphere:

- The furnace supports a wide range of gases, including air, Nitrogen (N2), Argon (Ar), Helium (He), Neon (Ne), Hydrogen (up to 5%), and rough vacuum.

- Multiple gas inlets and outlets with stainless steel ball valves and a flow meter allow precise control of the atmosphere within the chamber.

- The furnace chamber is welded and oil leak tested to ensure air-tightness, and the door is sealed with a high-temperature silicon gasket.

-

Vacuum and Pressure Management:

- The furnace is equipped with a KF40 vacuum port, allowing users to pre-vacuum the chamber before introducing inert or protective gases.

- Positive pressure inside the furnace is capped at 0.02 MPa / 150 torr / 3 psi.

-

Safety Features:

- Overheat protection automatically shuts down the furnace if the temperature exceeds safe limits or if the thermocouple malfunctions.

- Power failure protection ensures the furnace resumes operations seamlessly once power is restored.

- Built-in ammeter and dual voltmeters are included for easy monitoring of electrical parameters.

-

Cooling System:

- A built-in stainless steel water-cooling panel protects the furnace door’s sealing gasket, particularly during extended operations at high temperatures.

-

Multiple Atmosphere Processing:

- The furnace allows users to perform multiple atmosphere processes within a single cycle, such as binder burnout in air and sintering under an inert gas or rough vacuum environment.

-

Compliance and Warranty:

- The furnace is CE compliant and optionally ETL tested to UL and CSA standards.

- A 1-year warranty covers parts and labor (excluding heating elements).

Specifications:

-

Chamber Dimensions and Capacity:

- 12x8x8 inches (0.44 cu ft)

- 16x12x12 inches (1.33 cu ft)

- 20x16x16 inches (2.96 cu ft)

-

Heating Element:

- Molybdenum Silicide (MoSi2) heating elements ensure stable and efficient heating at high temperatures.

-

Temperature Control:

- Eurotherm 3204 (UK) or Shimaden FP93 (Japan) controllers, offering up to 50-segment ramp and dwell programming.

- Precision: ±1°C.

- Maximum Heating Rate: 15°C/min.

-

Maximum Working Temperatures:

- Air: 1750°C

- Helium (He), Neon (Ne), Argon (Ar): 1650°C

- Nitrogen (N2): 1500°C

- Hydrocarbon Gas: 1550°C

- Hydrogen (H2, up to 5%): 1500°C

- Rough Vacuum: 1400°C

-

Electrical Requirements:

- 16x12x12 model: 220V, single-phase

- 20x16x16 model: 480V, three-phase

-

Size and Weight:

-

12x8x8 model:

- Unit Dimensions: 26x31x44 inches

- Unit/Shipping Weight: 628/752 lbs

-

16x12x12 model:

- Unit Dimensions: 34x36x63 inches

- Unit/Shipping Weight: 914/1131 lbs

-

20x16x16 model:

- Unit Dimensions: 36x40x72 inches

- Unit/Shipping Weight: 1620/1830 lbs

-

12x8x8 model:

Applications:

The GCF1750 controlled atmosphere muffle furnace is versatile, serving a wide array of applications:

- Materials Sintering: Ideal for high-temperature sintering processes for ceramics, metals, and composites.

- Laboratory Research: Perfect for materials science, metallurgy, and other research requiring precise atmosphere and temperature control.

- Heat Treatment: Used for tasks such as heat-treating alloys, metals, and other materials that require a controlled environment.

- Semiconductor and Electronics Manufacturing: Necessary for processing materials that must be handled in specific atmospheric conditions.