Across International

3-Zone 1400°C Tube Furnace OD 80mm

3-Zone 1400°C Tube Furnace OD 80mm

SKU: TF1400.80.3

- Regular price

- Price: $18,990.00

- Regular price

- List Price: $22,341.17

- Sale price

- Price: $18,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

1400°C 1-3 Zone Tube Furnace with Alumina Tube (TF1400 Series)

The TF1400 series tube furnaces are designed for high-temperature processes, with a maximum temperature of 1400°C. They offer versatile configurations (1-zone, 2-zone, 3-zone) and provide high performance for various heat treatment, sintering, and calcination applications. The furnace features Mitsubishi (Japan) high-purity alumina insulation, SiC heating elements, and a precise Eurotherm (UK) digital controller for controlled, efficient operation.

Key Features:

-

High-Quality Insulation and Heating:

- The furnace chamber is insulated with Mitsubishi high-quality alumina fiber, known for its excellent thermal properties and minimal heat loss.

- SiC (Silicon Carbide) heating elements ensure uniform heating up to high temperatures, providing excellent longevity and performance.

-

Versatile Heating Zones:

- Available in 1-zone, 2-zone, and 3-zone configurations to tailor the furnace for processes requiring different temperature zones.

- The 2-zone and 3-zone options provide precise temperature control across the length of the tube, suitable for multi-step processes.

-

Advanced Temperature Control:

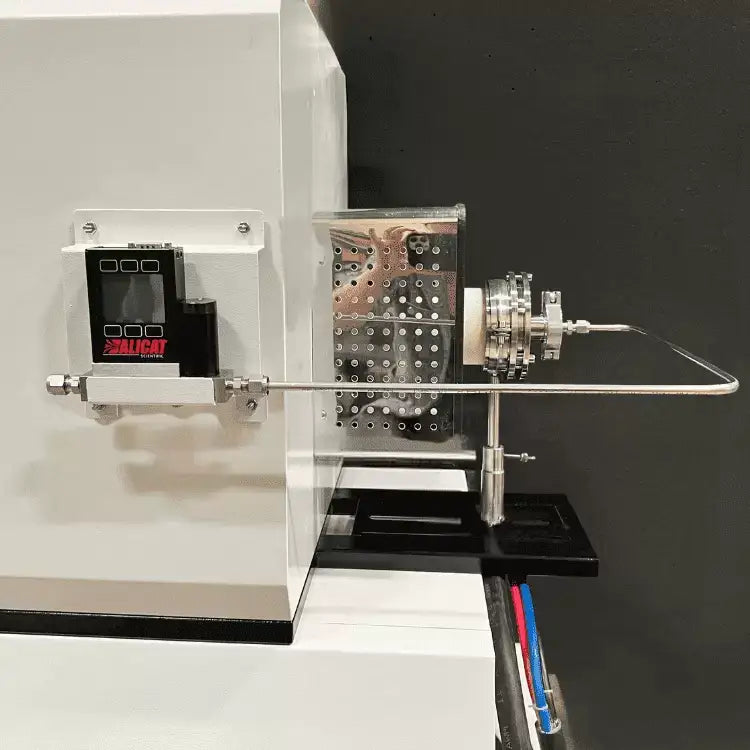

- The furnace is controlled by a Eurotherm (UK) digital multi-segment controller with self-tuning PID control, offering precise temperature regulation with minimal overshoot.

- The furnace is equipped with a built-in digital communication port, allowing remote control and monitoring via a PC, and saving or exporting test results for analysis.

-

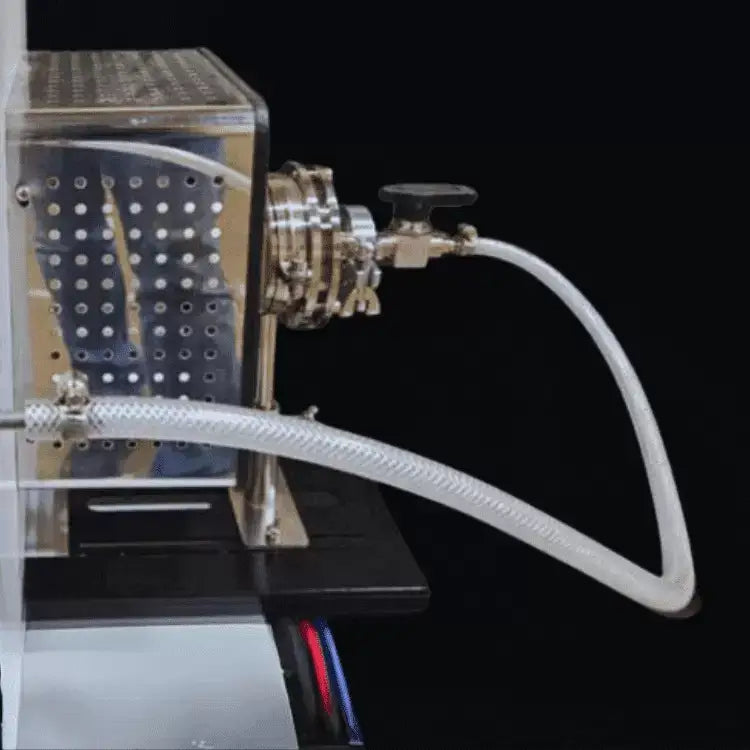

Atmospheric Control:

- The furnace is equipped with stainless steel vacuum sealing flanges, valves, and a pressure meter, enabling the creation of controlled atmospheres, including vacuum or inert gas environments, for processes such as binder burnout and sintering.

- Rated vacuum pressure: 0.001 Pa (0.00001 mbar), suitable for high-vacuum processes.

-

Safety Features:

- Overheat protection: The furnace shuts down automatically if the temperature exceeds the set limit or if there is a thermocouple failure.

- Power failure protection ensures operation resumes after a power outage.

-

Certification:

- The furnace is ETL tested to UL and CSA standards and is CE certified, ensuring it meets international safety and performance standards.

Specifications:

Furnace:

- Electrical Requirements: 208-240V, 50/60Hz, single-phase

- Tube Material: High purity (99%) Al2O3 alumina

- Maximum/Constant Working Temperature: 1400°C (2552°F) / 1300°C (2372°F)

- Rated Vacuum Pressure: 0.001 Pa / 0.0075 millitorr / 0.00001 mbar

- Rated Positive Pressure: 0.02 MPa / 150 torr / 3 psi

- Refractory Lining: Mitsubishi high-quality 1600-grade fiber alumina

- Heating Element: SiC (Silicon Carbide)

- Thermocouple Type: S-type

- Temperature Controller: Eurotherm (UK) multi-segment digital controller

- Max Heating Rate: 5°C/min (above 1200°C) and 10°C/min (below 1200°C)

- Temperature Controller Precision: ±1°C

- Vacuum Sealing Flange Kit: Stainless steel vacuum sealing flanges with one vacuum gauge, two valves, and four thermal ceramic blocks.

Model Configurations:

1-Zone:

- Tube Size: 60mm OD x 1000mm L, 100mm OD x 1000mm L, 120mm OD x 1000mm L, 150mm OD x 1000mm L

- Maximum Output: 4 kW to 9 kW (depending on tube size)

- Furnace Dimensions: 25" x 19" x 27"

- Shipping Dimensions: 47" x 35" x 39"

- Weight: 265-370 lbs (unit weight), 400-500 lbs (shipping weight)

2-Zone:

- Tube Size: 60mm OD x 1200mm L, 100mm OD x 1200mm L

- Output: 10 kW to 12 kW

- Furnace Dimensions: 25" x 19" x 27" to 28" x 20" x 30"

- Shipping Dimensions: 47" x 35" x 39" to 50" x 38" x 42"

- Weight: 265-350 lbs (net weight), 400-450 lbs (shipping weight)

3-Zone:

- Tube Size: 60mm x 1300mm, 100mm x 1300mm (OD x length)

- Maximum Output: 3.5 kW per zone (Total 10.5 kW per furnace)

- Furnace Dimensions: Typically larger than 2-zone models, dimensions vary

- Weight and Shipping: Larger and heavier than 2-zone configurations

Applications:

The TF1400 series tube furnaces are ideal for a wide range of high-temperature applications:

- Material Sintering: Used in ceramics, metals, and composites for sintering at high temperatures.

- Calcination and Thermal Treatment: Ideal for thermal treatments, including binder burnout and decomposition processes.

- Vacuum and Inert Gas Processing: Suitable for operations under controlled vacuum or inert atmospheres.

- Research and Development: Often used in laboratories for research into new materials or high-temperature processes.

Conclusion:

The TF1400 series offers a reliable and flexible solution for high-temperature processing. With a variety of tube sizes and zone configurations, as well as robust safety features, it is well-suited for industries and research facilities requiring precise temperature control and atmospheric conditions. Its advanced features, including remote monitoring and multiple atmosphere processing, make it a powerful tool for materials science and thermal processing.