Across International

3-Zone 1500C Top-Open Tube Furnace with Alumina Tube and Sealing Flanges OD 80mm

3-Zone 1500C Top-Open Tube Furnace with Alumina Tube and Sealing Flanges OD 80mm

SKU: STF1500.80.3

- Regular price

- Price: $19,990.00

- Regular price

- List Price: $23,517.64

- Sale price

- Price: $19,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

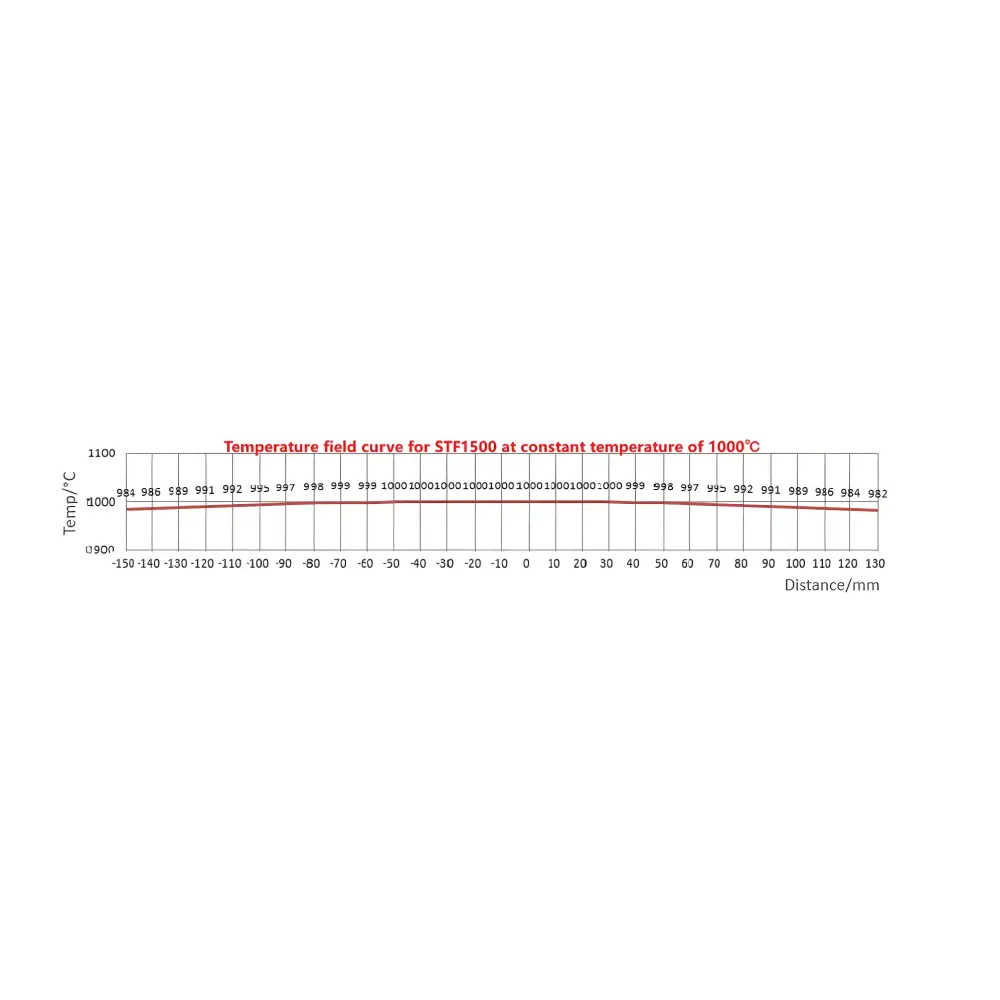

1500°C 1-3 Zone Top-Open Tube Furnace with Alumina Tube and Sealing Flanges (STF1500 Series)

The STF1500 series furnaces are designed for high-temperature applications with a maximum temperature of 1500°C, offering precision control and versatile processing options. These top-open tube furnaces are available in 1-zone, 2-zone, and 3-zone configurations, allowing flexibility in thermal treatments and multi-step processes under controlled atmospheric conditions.

Key Features:

-

High-Quality Insulation and Heating:

- The furnace features Mitsubishi (Japan) high-purity alumina fiber insulation for excellent thermal efficiency and minimal heat loss.

- SiC (Silicon Carbide) heating elements are used to achieve uniform heating with high stability. These elements are suitable for reaching and maintaining high temperatures in demanding applications.

-

Multiple Heating Zones:

- The furnace is available in 1-zone, 2-zone, and 3-zone configurations for more precise temperature control across different parts of the tube. Each zone can be independently controlled for customized thermal gradients and processes.

-

Temperature Control:

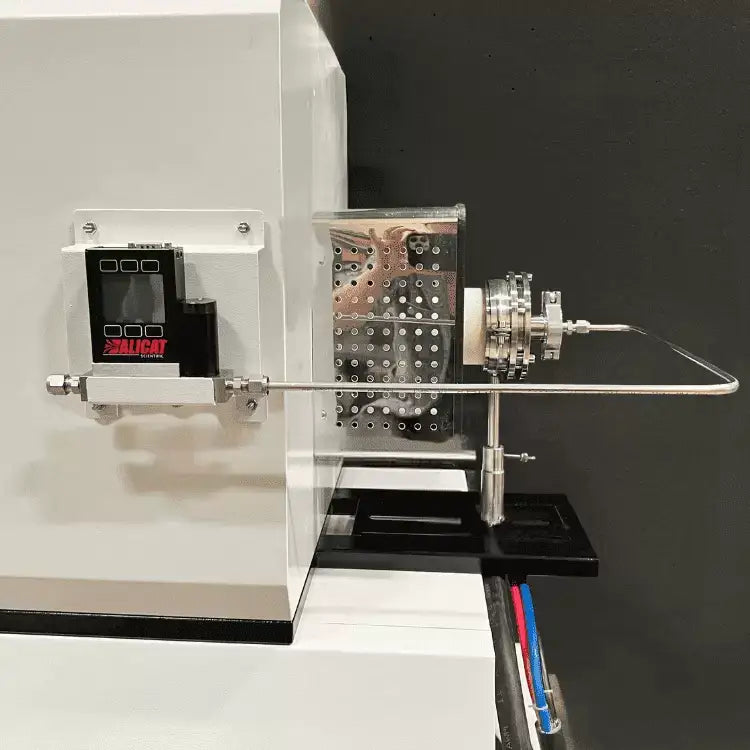

- The furnace is controlled by a Eurotherm (UK) digital multi-segment controller, which provides precise control and monitoring. The self-tuning PID control minimizes overshoot and ensures accurate temperature regulation.

- The temperature controller precision is ±1°C, ensuring high repeatability and consistency.

-

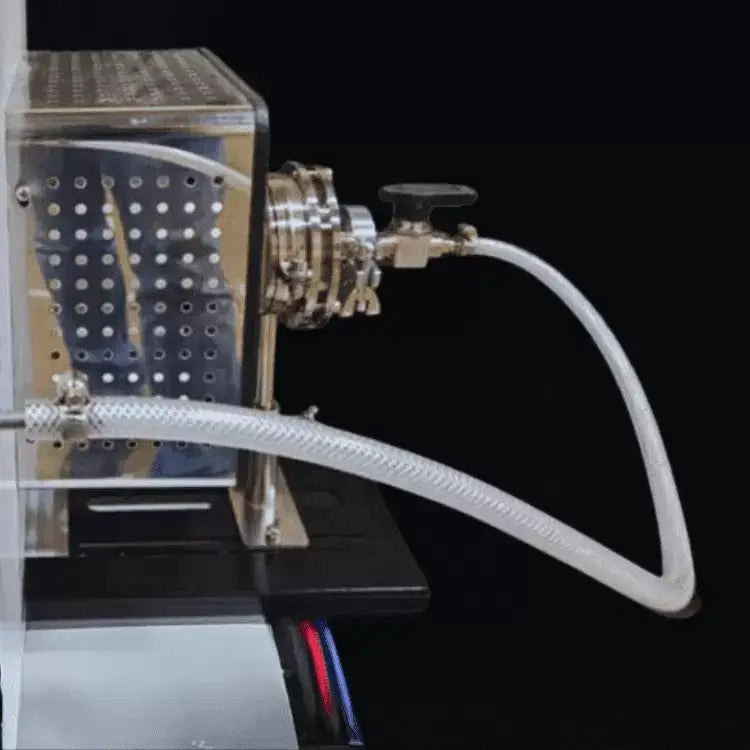

Atmospheric Control:

- Multiple atmosphere processes can be conducted within a single cycle (e.g., binder burnout in air and parts sintering under vacuum or inert gas environments).

- Includes stainless steel vacuum sealing flanges, valves, and pressure meters for managing gas flow and creating vacuum or inert atmospheres.

-

Safety Features:

- Overheat protection: The furnace will shut down if the temperature exceeds the set range or if the thermocouple malfunctions.

- Power failure protection ensures the furnace resumes operation after a power interruption.

-

Compact and Portable Design:

- The furnace is designed for easy mobility and can be conveniently installed in various laboratory or industrial settings.

Specifications:

Furnace:

- Electrical Requirements: 208-240V, 50/60Hz, single phase

- Tube Material: High purity (99%) Al2O3 alumina

- Maximum Working Temperature: 1500°C (with a maximum continuous runtime of 2 hours)

- Constant Working Temperature: 1400°C

- Rated Vacuum Pressure: 0.001 Pa / 0.0075 millitorr / 0.00001 mbar

- Rated Positive Pressure: 0.02 MPa / 150 torr / 3 psi

- Heating Element: SiC (Silicon Carbide)

- Thermocouple Type: S-type

- Refractory Lining: Mitsubishi (Japan) 1600-grade fiber alumina

- Temperature Controller: Eurotherm (UK) multi-segment digital controller

- Max Heating Rate: 5°C/min (above 1200°C) and 10°C/min (below 1200°C)

- Temperature Controller Precision: ±1°C

- Vacuum Sealing Flange Kit: Stainless steel vacuum sealing flanges with one vacuum gauge, two valves, and four thermal ceramic blocks.

Model Comparison:

| Zone Configuration | 1-Zone | 1-Zone | 2-Zone | 2-Zone | 3-Zone | 3-Zone |

|---|---|---|---|---|---|---|

| Tube Size (OD x L) | 60mm x 1.2m | 80mm x 1.2m | 60mm x 1.2m | 80mm x 1.2m | 60mm x 1.4m | 80mm x 1.4m |

| Heating Zone Length | 15.4" | 15.4" | 7.5" + 7.5" | 7.5" + 7.5" | 7.5" + 7.5" + 7.5" | 7.5" + 7.5" + 7.5" |

| Maximum Output | 6 kW | 6 kW | 6 kW | 6 kW | 9 kW | 9 kW |

| Eurotherm Controller | 1 pc | 1 pc | 2 pcs | 2 pcs | 3 pcs | 3 pcs |

| Furnace Dimensions (L x W x H) | 23x15x41" | 26x17x43" | 23x15x41" | 26x17x43" | 27x19x45" | 30x21x47" |

| Shipping Dimensions (L x W x H) | 37x21x46" | 37x21x46" | 37x21x46" | 37x21x46" | 41x25x51" | 41x25x51" |

| Shipping Weight (lbs) | 485 | 550 | 485 | 550 | 530 | 630 |

Applications:

The STF1500 tube furnace is ideal for high-temperature processes such as:

- Sintering, calcination, and thermal treatments of various materials.

- Binder burnout in air followed by sintering under vacuum or inert gases.

- Material research, including testing ceramics, composites, and metals at extreme temperatures.

- Suitable for laboratories and industries requiring precise control over temperature, atmosphere, and vacuum.

Conclusion:

The STF1500 series furnaces provide precise control and excellent thermal performance at temperatures up to 1500°C, making them suitable for a wide range of high-temperature applications. Their modular zone configurations offer flexibility in process optimization, while their robust insulation, vacuum sealing, and safety features ensure reliable and consistent results.