Across International

45KW Low-Frequency Dual-Station Induction Heater 1-20KHz

45KW Low-Frequency Dual-Station Induction Heater 1-20KHz

SKU: IHL45AB

- Regular price

- Price: $13,990.00

- Regular price

- List Price: $16,458.82

- Sale price

- Price: $13,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

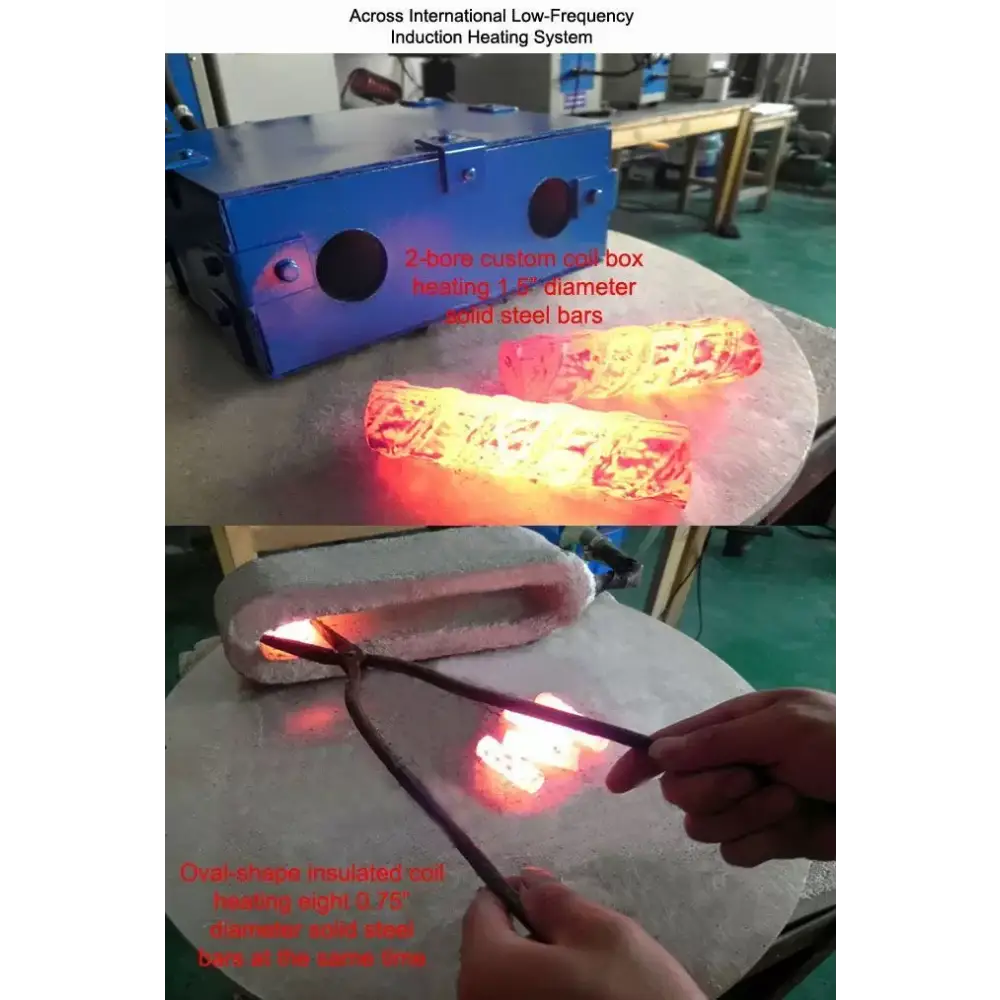

45KW Low-Frequency Dual-Station Induction Heater (1-20kHz)

The 45KW Low-Frequency Induction Heater from Across International is a high-performance heating system designed to meet the demands of various industrial applications. Operating within the 1 kHz to 20 kHz frequency range, this induction heater is highly efficient for deep heat penetration, making it suitable for metal hardening, steel rod forging, tempering of pressing dies, pre-heating for welding, and melting metal batches over 4 lbs. Unlike traditional heaters, this system works effectively with both ferrous and non-ferrous metals.

Key Features:

-

Wide Frequency Range (1-20 kHz):

The system is capable of adjusting to the most optimal resonant frequency for efficient heating, depending on the material type, heating requirements, and size of the workpieces. It ensures effective and uniform heating. -

45KW Power Output:

The high 45KW power output enables the machine to handle more demanding applications, including larger metal batches and more intense heating needs. The system is built to handle continuous operation with a 100% duty cycle (24/7 usage). -

Dual-Station Capability:

This model features dual-station functionality, allowing for the simultaneous heating of two workpieces, improving productivity and efficiency in industrial operations. -

Efficient Cooling System:

The induction heater is equipped with rear air cooling and relies on circulating water to maintain the optimal operational temperature. It requires water flow rates greater than 1 gallon (4 liters) per minute and a water pressure of at least 29 PSI to ensure proper cooling during continuous operation. -

Safety Features:

- Overvoltage Protection: Automatically shuts down if the input voltage exceeds 245V, with an indicator light and buzzer sounding until the voltage returns to a safe level.

- Overheat Protection: The system will automatically shut down if the IGBT heat sink temperature exceeds 55°C. This protects the unit from potential damage and ensures safe operation.

- Overcurrent/Malfunction Protection: The system includes safeguards against overheating, short circuits, and other malfunctions, with visual and audible alarms to indicate any issues.

- Low Water Pressure Protection: The heater will shut down if the water pressure falls below 29 PSI to prevent overheating.

-

Digital Output Displays:

The system features digital displays to show frequency and current in real time, enabling precise control over the heating process. -

Manual and Automatic Modes:

Users can switch between manual and automatic modes to optimize the heater's performance based on specific needs and materials.

Specifications:

-

Max. Input Current: 55 A (requires a minimum 70A circuit breaker)

-

Power Input: 480 VAC, 50/60Hz three-phase (380V available upon request)

-

Power Cord: 4-gauge, 4-conductor, max 60A (4/4 SOOW for 3-phase system)

-

Output Frequency: 1-20 kHz

-

Output Current: 10-70A

-

Output Voltage: 70-550V

-

Max. Oscillating/Power Input: 45KW

-

Duty Cycle: 100% continuous operation (24/7)

-

Cooling: Air cooling with rear fan, requiring pure water for cooling

-

Water Pressure: ≥ 0.2 Mpa (29 PSI); tap water and water pump (>1/4HP & >240 Gph) can be used

-

Water Flow: ≥ 1 gallon (4 liters) per minute

-

Unit Dimensions:

- Power Supply: 10.5 x 22 x 18.5 inches

- Transformer: 19 x 23 x 29 inches

-

Shipping Dimensions: 32 x 26 x 29 inches

-

Shipping Weight: 188 lbs

-

Connection Cables: 7 feet

Applications:

- Metal Heating: Suitable for deep heat penetration needed in applications like hardening, forging, and tempering.

- Pre-heating for Welding: Effective for pre-heating metals to proper temperatures for welding.

- Melting Metals: Capable of melting metal batches over 4 lbs, including ferrous and non-ferrous metals.

Conclusion:

The 45KW Low-Frequency Dual-Station Induction Heater is a powerful, versatile tool for industrial heating applications. With its dual-station functionality, wide frequency range, and comprehensive safety features, it offers a highly efficient solution for a range of tasks, including metal forging, hardening, and pre-heating for welding. This system is designed for continuous operation and provides precise control over heating parameters to ensure optimal results.