Across International

6.6KW Hi-Frequency Induction Heater 600-1100KHz

6.6KW Hi-Frequency Induction Heater 600-1100KHz

SKU: IHG06A3

- Regular price

- Price: $5,990.00

- Regular price

- List Price: $7,047.06

- Sale price

- Price: $5,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

6.6KW Hi-Frequency Induction Heater (600-1100KHz)

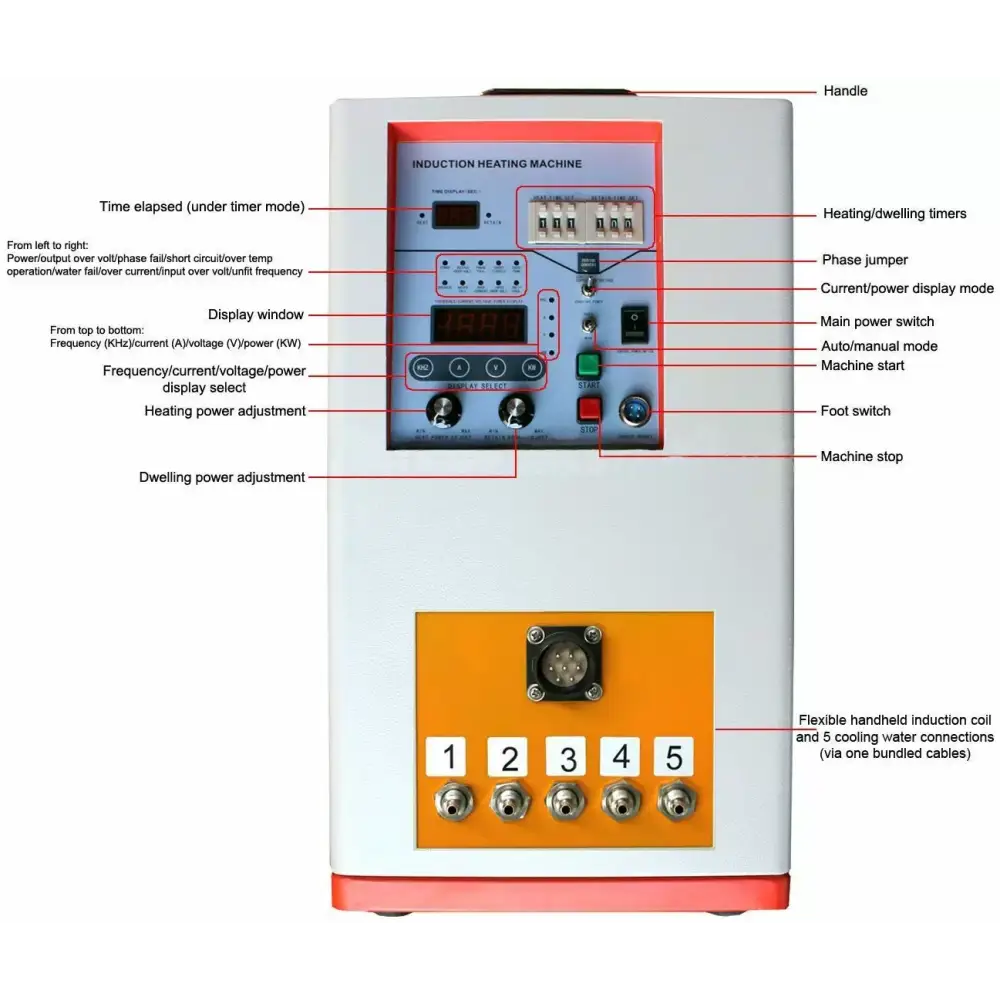

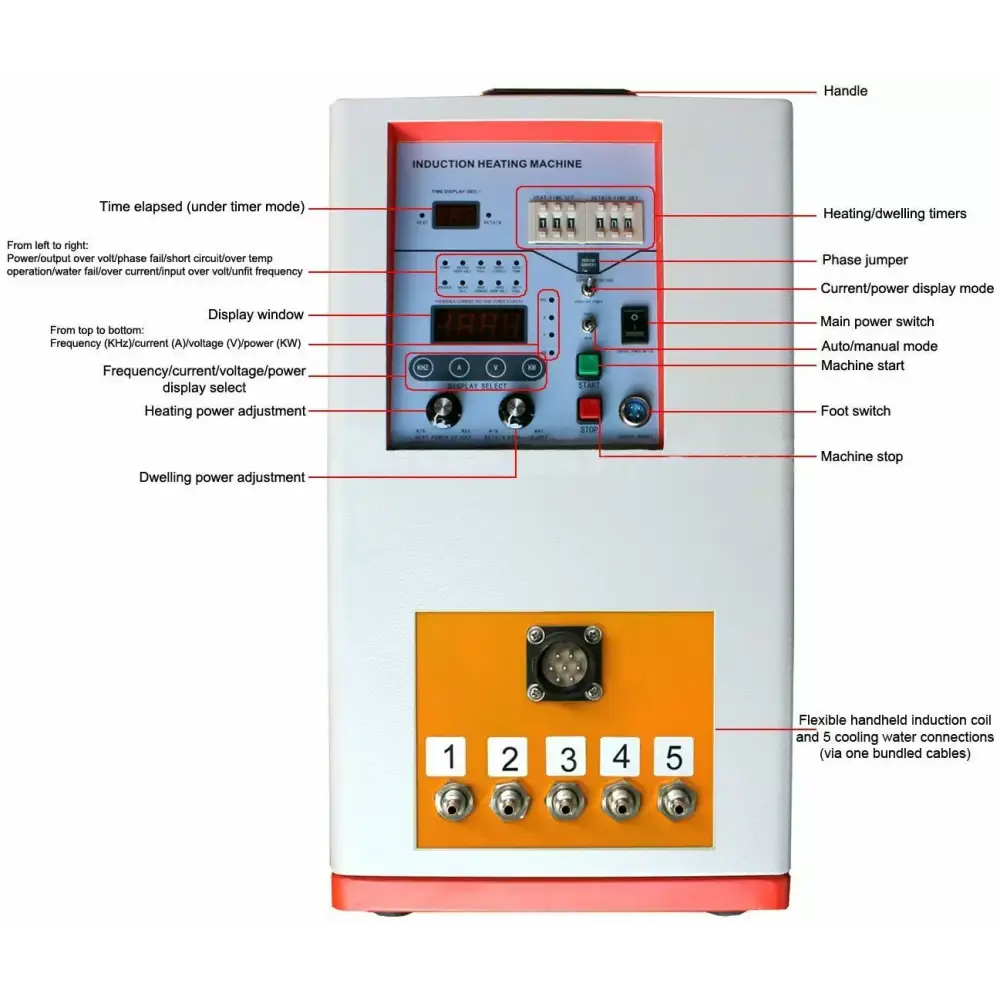

The 6.6KW Hi-Frequency Induction Heater (600-1100KHz) is an advanced heating system designed for applications requiring precise, rapid heating of small metallic components. It operates at high frequencies between 600 kHz and 1100 kHz, making it ideal for heating metals that other frequencies cannot heat efficiently, such as aluminum and metal powders. This heater is particularly suited for fine steel wire annealing (such as those used in dentistry), small precision shaft quenching, hard alloy saw blade brazing, and melting metal powders.

Key Features:

-

High-Frequency Operation (600-1100 KHz):

The heater operates within the 600-1100 kHz range, allowing it to heat materials such as aluminum and metal powders that lower frequencies cannot effectively address. Its high frequency enables efficient heating of small components, offering versatility and precision. -

Compact and Lightweight Design:

The power supply unit weighs 35 lbs, and the handheld coil station is just 3 lbs, making it easy to handle and transport. The unit’s compact design (21x10x18" for the power supply) ensures it fits into smaller spaces. -

Quick Heating and Precision:

The unit provides fast heating times and is perfect for fine-tuned applications like annealing small wires or brazing alloy blades. The heater’s precision helps achieve high-quality results in short cycles, making it ideal for high-precision tasks. -

Safety Features:

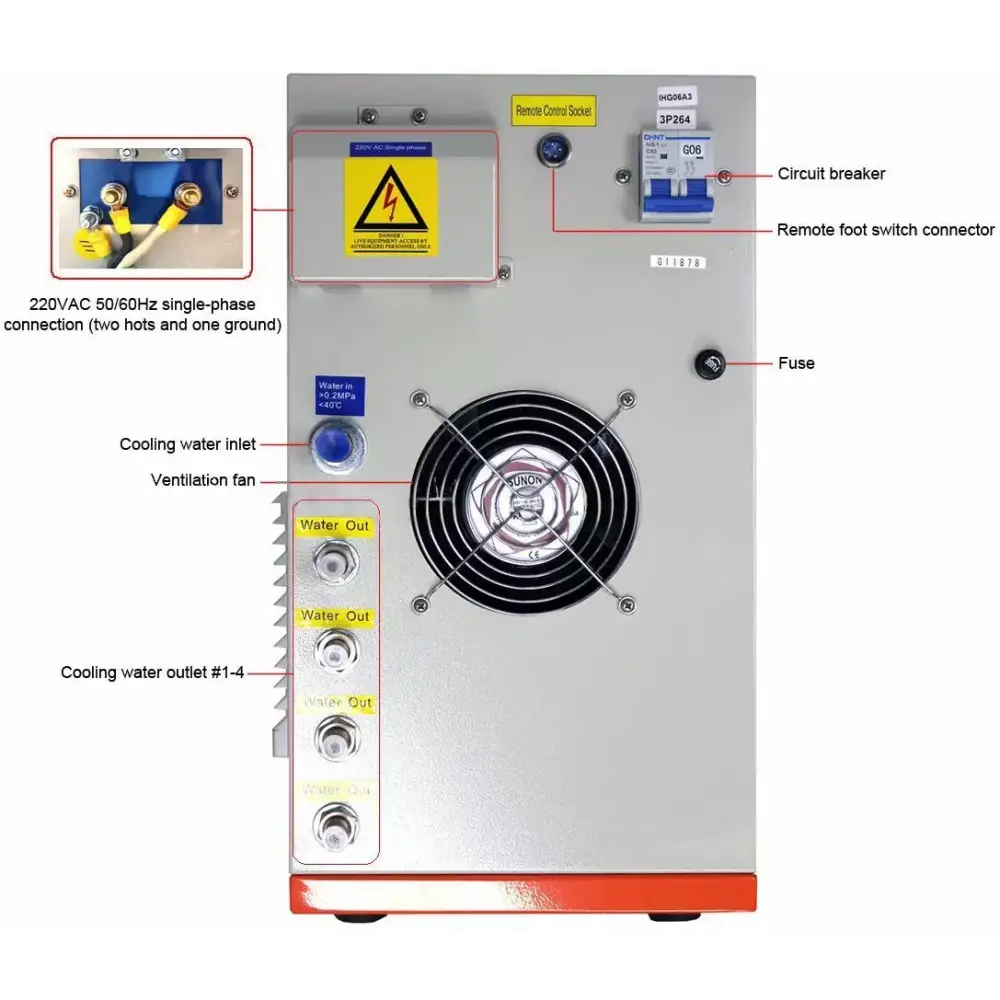

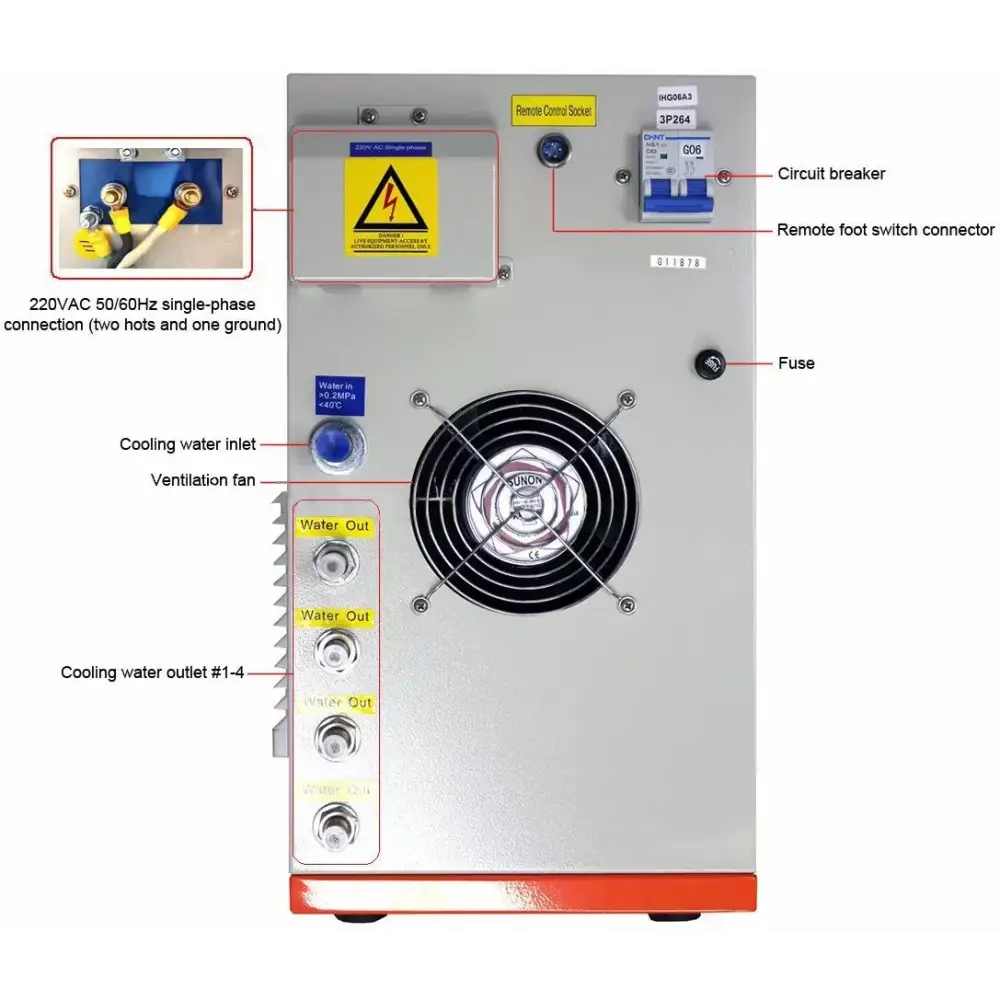

- Overvoltage Protection: The machine automatically shuts down if the input voltage exceeds 245V, with a buzzer and light alert to notify users.

- Overheat Protection: If the IGBT heat sink temperature exceeds 55°C, the unit will shut down and alert the operator with an overheat light and buzzer.

- Overcurrent/Malfunction Protection: The heater will shut down if a malfunction occurs, including overheating, signal interference, or short circuits, ensuring safe operation.

- Low Water Pressure Protection: If the water pressure drops below 29 PSI, the heater shuts down to protect the system.

-

Ease of Use and Setup:

The unit is designed for user-friendliness, with clear instructions that allow quick setup. The heating and dwelling timers can be adjusted from 0.1 to 99.9 seconds, offering flexibility for various heating tasks. -

Energy Efficiency:

Induction heating is known for its efficiency, as it directly heats the workpiece without wasting energy. This model saves energy by minimizing heat loss and providing rapid, localized heating. -

Cooling System Requirements:

- Water Pressure: Requires a minimum of 40 PSI, and the system uses tap water.

- Water Flow: The machine needs a water flow of more than 0.8 gallons (3 liters) per minute.

- Cooling Fan: Air cooling is provided through a rear fan, ensuring the system operates within safe temperature ranges.

-

Customizable Coils:

Custom coils can be made upon request, allowing the system to be tailored to specific heating applications. The default coil configuration is a standard size, and modifications can be made to meet your needs.

Specifications:

- Max Input Current: 30A (requires 40A single-phase circuit breaker)

- Power Input: 208-240V, 50/60Hz, single-phase

- Max Oscillating Power: 6.6KW

- Duty Cycle: 80%

- Heating Timer: Adjustable from 0.1 to 99.9 seconds

- Dwelling Timer: Adjustable from 0.1 to 99.9 seconds

- Cooling System: Rear fan for air cooling

- Induction Coil: Standard coil size, custom coils available (diameter and length customized)

- Water Pressure: ≥ 40 PSI

- Water Flow: > 0.8 gallons (3 liters) per minute

-

Weight:

- Power supply: 35 lbs

- Handheld coil station: 3 lbs

- Shipping weight: 50 lbs

-

Dimensions:

- Power supply: 21"x10"x18"

- Handheld coil station: 4"x6"x4"

- Shipping dimensions: 27"x15"x28"

- Connection Cables: 6 feet

- Remote Foot Switch: 7 feet

Melting Capacity (Approx.):

- Steel & Stainless Steel: Ideal for small-scale parts (specific weight capacities not listed)

- Brass, Copper, Gold, Silver: Suitable for precise heating and small part brazing

- Aluminum & Aluminum Alloy: Efficient for melting small parts and powders

Conclusion:

The 6.6KW Hi-Frequency Induction Heater (600-1100KHz) is a versatile, high-efficiency tool for precision heating, ideal for industries such as dental, metalworking, and small-scale brazing. Its high-frequency operation and customizable coils make it perfect for fine materials, while its compact, portable design makes it easy to set up and use. The added safety features and energy-efficient operation ensure reliable performance and long-term durability