Across International

60KW Hi-Frequency Split Induction Heater 30-150KHz

60KW Hi-Frequency Split Induction Heater 30-150KHz

SKU: IHG60AB

- Regular price

- Price: $26,990.00

- Regular price

- List Price: $31,752.94

- Sale price

- Price: $26,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

60KW Hi-Frequency Split Induction Heater (30-150 KHz)

The IHG Series 60KW Hi-Frequency Split Induction Heater is a powerful, high-efficiency heating system designed for specialized applications, including metal melting, brazing, quenching, and annealing. Operating at a frequency range of 30-150 KHz, this heater is ideal for materials like aluminum, fine steel wires, and metal powders, which are challenging to heat with standard induction heaters. It is also capable of heating parts from a distance, making it suitable for industries such as metalworking, jewelry production, and precision manufacturing.

Key Features:

-

Wide Frequency Range (30-150 KHz):

This heater operates in a frequency range that makes it especially effective for heating metals like aluminum and fine powders, materials that can be difficult to heat with lower frequency induction units. -

High Power Output (60KW):

The unit provides 60KW of input power, which is ideal for industrial-scale heating and metal processing. It is capable of handling larger parts and materials compared to smaller induction heaters. -

Multiple Safety Features:

- Overvoltage Protection: Automatically shuts the system down if the input voltage exceeds 245V. Includes an alarm and light indicator.

- Overheat Protection: Shuts down the system if the IGBT heat sink temperature exceeds 55°C, with an alarm alert to increase water pressure or lower the water temperature.

- Overcurrent and Malfunction Protection: The system will shut down if overheating, signal interference, short-circuiting between workpieces and coils, or other malfunctions are detected.

- Low Water Pressure Protection: The system will shut down if water pressure falls below 29 PSI, maintaining the integrity of the cooling system.

-

Cooling Requirements:

- The unit requires clean, circulating water at a temperature below 45°C.

- A water pump with a flow rate of 5 liters per minute (240 Gph) is necessary for effective cooling.

- Air cooling via a rear fan ensures efficient temperature regulation during operation.

-

Operational Timers:

- Heating Timer: Adjustable between 1-99.9 seconds to provide precise control over heating time.

- Dwelling Timer: Adjustable between 1-99.9 seconds for controlled dwell time during the heating cycle.

-

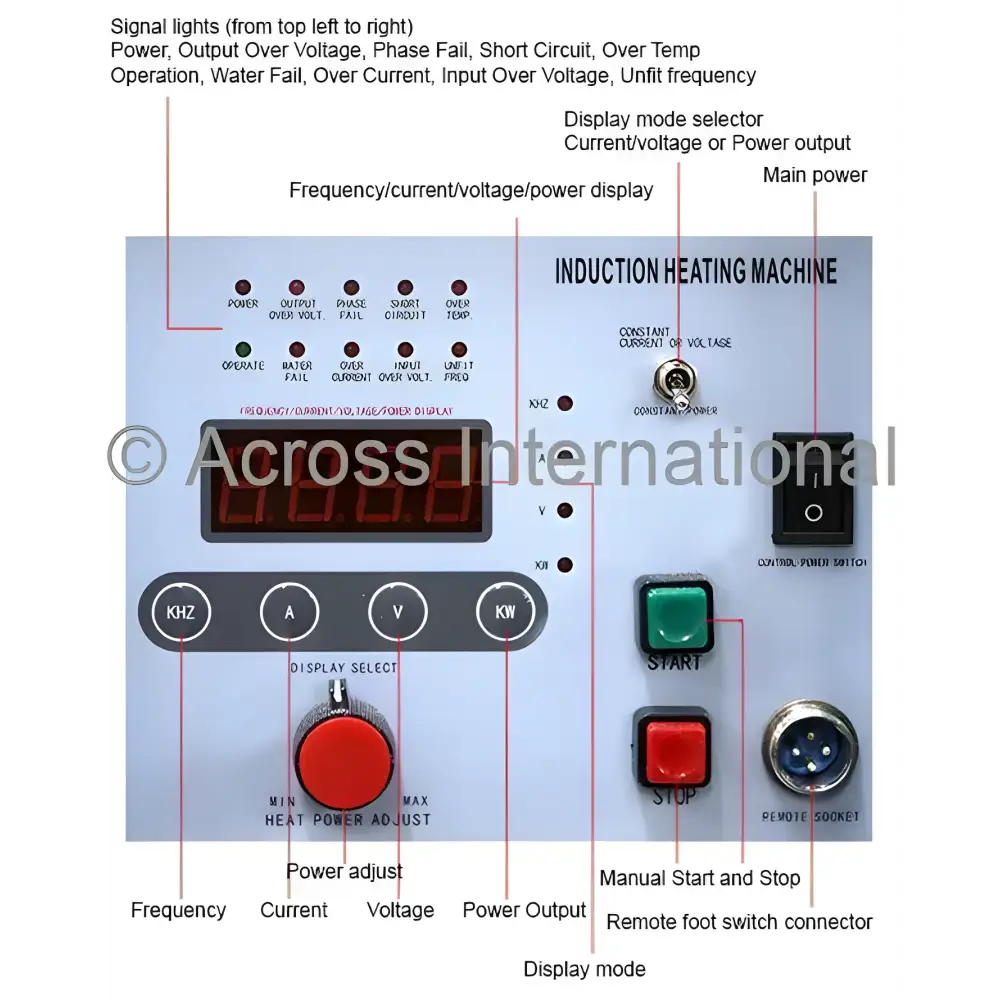

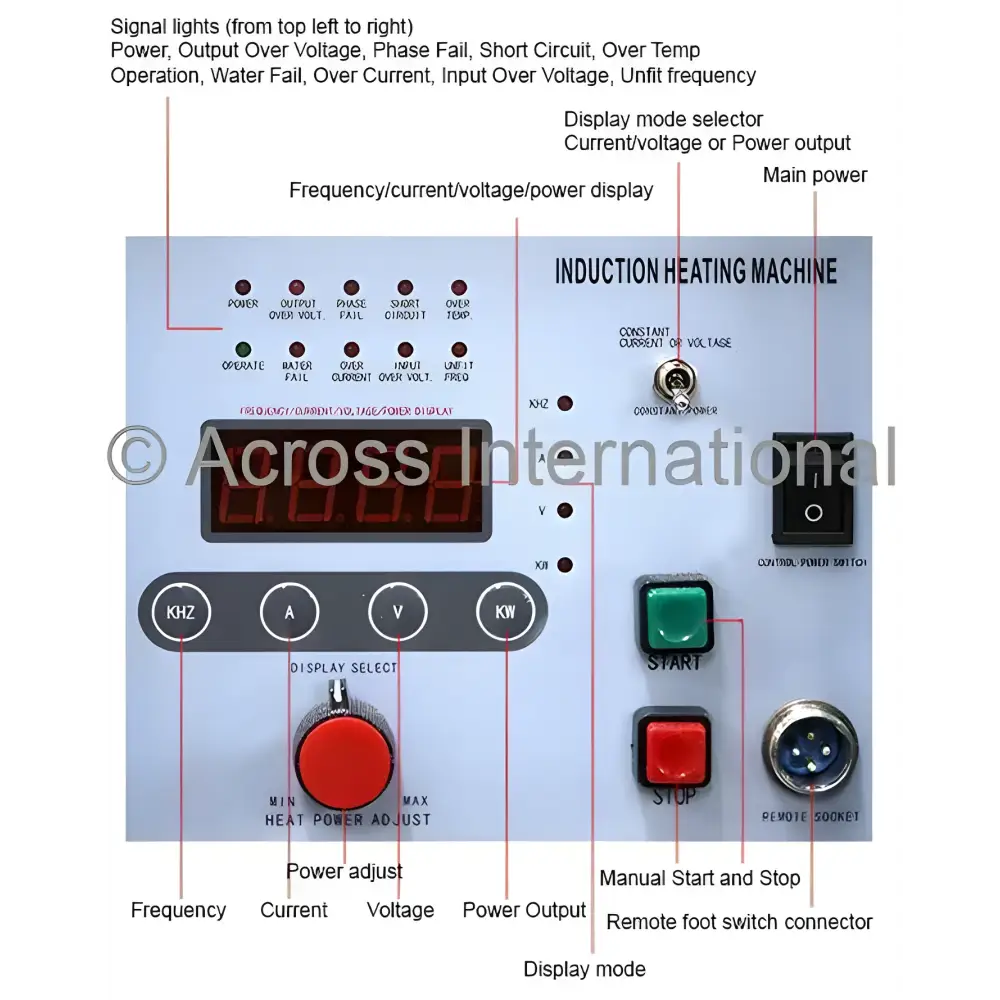

Remote Operation:

Includes a 7-foot remote foot switch, allowing the operator to control the unit remotely for greater flexibility and convenience during use.

Safety Notes:

- Always wear protective gear and goggles when operating the machine.

- Crucibles should always be covered during operation to avoid hazardous exposure.

- Do not run the unit no-load for long periods, as it may damage the system.

- Ground the machine properly during operation to prevent electrical hazards.

- Thread tape or similar materials should not be used when installing induction coils.

Specifications:

-

Maximum Input Current:

75A (requires a 95A three-phase circuit breaker). -

Power Supply:

460 VAC, 50/60Hz, three-phase. -

Output Frequency:

30-150 KHz. -

Input Power:

60 KW. -

Duty Cycle:

100% (can operate 24 hours a day without interruption). -

Water Requirements:

- Pressure: ≥ 0.2 Mpa (29 PSI).

- Flow: > 1.4 gallons (5 liters) per minute.

-

Weight:

- Power Supply Unit: 150 lbs.

- Heater Unit: 80 lbs.

-

Induction Coil:

Custom-made coils based on user requirements. -

Remote Foot Switch:

7-foot remote switch for convenient operation.

Applications:

-

Metal Melting and Heating:

The 60KW heater can melt and heat various metals such as steel, stainless steel, aluminum, brass, copper, gold, and silver, offering versatility for different applications. -

Brazing and Annealing:

Ideal for fine steel wire annealing (e.g., dental wires), brazing hard alloy saw blades, and other metal forming processes. -

Precision Shaft Quenching:

Suitable for small precision shaft quenching in industries requiring high-precision metal processing. -

Metal Powders:

Capable of heating and melting metal powders efficiently for use in specialized industrial processes.

Melting Capacities:

The induction heater can handle the following approximate melting capacities:

-

Steel, Stainless Steel:

Can melt up to 18 kg of steel. -

Brass, Copper, Gold, Silver:

Can melt up to 50 kg of brass or copper, or 150 kg of gold or silver. -

Aluminum and Aluminum Alloys:

Can melt up to 18 kg of aluminum or aluminum alloys.

Conclusion:

The 60KW Hi-Frequency Split Induction Heater is a highly efficient and versatile heating solution for a range of industrial applications. Its high power output, wide frequency range, and multiple safety features make it ideal for precise metal heating tasks such as melting, brazing, and quenching. This unit is especially beneficial for industries dealing with difficult-to-heat materials like aluminum and metal powders, and offers advanced features like remote operation and customizable induction coils to suit various needs.