Across International

70KW Low-Frequency Dual-Station Induction Heater 1-20KHz

70KW Low-Frequency Dual-Station Induction Heater 1-20KHz

SKU: IHL70AB

- Regular price

- Price: $20,990.00

- Regular price

- List Price: $24,694.12

- Sale price

- Price: $20,990.00

- Unit price

- / per

Couldn't load pickup availability

9999 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

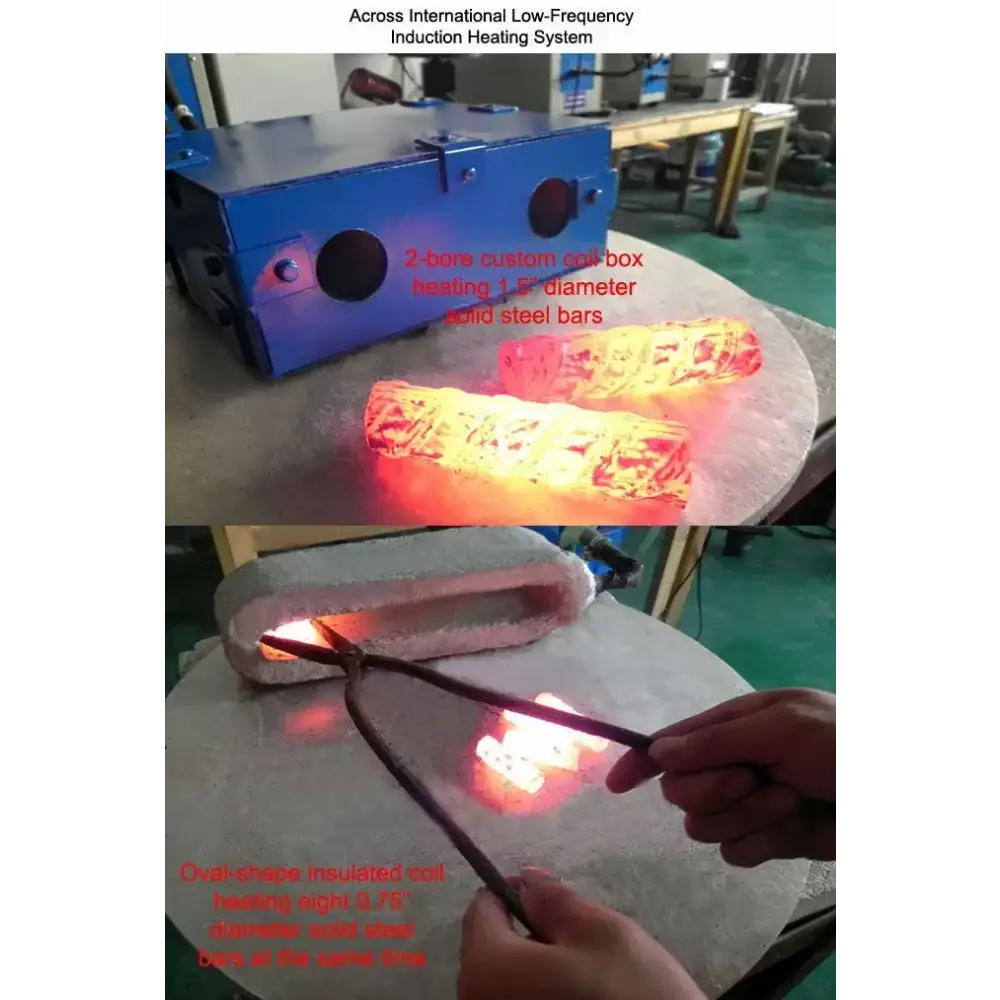

70KW Low-Frequency Dual-Station Induction Heater (1-20kHz)

The 70KW Low-Frequency Dual-Station Induction Heater by Across International is an industrial-grade system designed for a variety of metal heating applications. With a frequency range of 1 kHz to 20 kHz, this machine is particularly effective for processes that require deep heat penetration, such as full hardening, steel rod forging, tempering of pressing dies, pre-heating for welding, and melting metal batches over 4 lbs. It is versatile, supporting both ferrous and non-ferrous materials.

Key Features:

-

Wide Frequency Range (1-20 kHz):

The induction heater adjusts to the optimal resonant frequency for different materials and heating requirements, ensuring the most efficient and precise heating, regardless of workpiece size or material. -

70KW Power Output:

With a robust 70KW power output, this system can handle demanding industrial tasks that require substantial heating power. It is capable of continuous operation with a 100% duty cycle (24/7). -

Dual-Station Capability:

This model allows for dual-station operation, meaning two workpieces can be heated simultaneously, improving productivity and efficiency in various applications. -

Air and Water Cooling Systems:

The unit includes rear air cooling, while circulating water ensures optimal temperature regulation. The system requires water with a flow rate of at least 1.6 gallons (6 liters) per minute and a minimum water pressure of 29 PSI for proper operation. -

Safety Features:

- Overvoltage Protection: The heater shuts down if the input voltage exceeds 245V, with an alarm and light indicator until the voltage normalizes.

- Overheat Protection: The system will automatically stop if the IGBT heat sink temperature exceeds 55°C, preventing damage and ensuring safe operation.

- Overcurrent/Malfunction Protection: The machine shuts down in cases of overheating, signal interference, short circuits, or other failures, with alarms to alert the user.

- Low Water Pressure Protection: If water pressure drops below 29 PSI, the system will automatically shut down.

-

High Precision Control:

Digital output displays show real-time frequency and current readings, allowing precise adjustments for specific heating requirements. The system operates in both manual and automatic modes, providing flexible control options for different applications.

Specifications:

-

Max. Input Current: 88 A (requires a minimum 110A 3-phase circuit breaker)

-

Power Input: 460 VAC, 50/60Hz three-phase (380V available upon request)

-

Output Frequency: 1-20 kHz

-

Max. Oscillating/Power Input: 70KW

-

Output Current: 20-130A

-

Output Voltage: 70-550V

-

Duty Cycle: 100% (24/7 continuous operation)

-

Cooling: Rear air fan, requiring circulating water for temperature regulation

-

Water Pressure: ≥ 0.2 Mpa (29 PSI); can use tap water and water pump (>1/4HP & >240 Gph)

-

Water Flow: ≥ 1.6 gallons (6 liters) per minute

-

Unit Dimensions and Weight:

- Power Supply: 30 x 16 x 34 inches, 165 lbs

- Transformer: Size and weight depend on the workpiece type and heating requirements

-

Shipping Details:

- Connection Cables: 7 feet

Applications:

- Metal Heating and Hardening: Ideal for processes such as metal hardening, forging, tempering, and pre-heating for welding.

- Metal Melting: Capable of melting metal batches over 4 lbs, including steel, brass, copper, gold, silver, and aluminum alloys.

Melting Capacities:

| Metal Type | Steel, Stainless Steel | Brass, Copper, Gold, Silver | Aluminum and Aluminum Alloy |

|---|---|---|---|

| IH-70 (70KW) | 25KG | 100KG | 25KG |

Conclusion:

The 70KW Low-Frequency Dual-Station Induction Heater is a powerful and versatile tool for industrial heating applications. Its dual-station functionality, high power output, and comprehensive safety features make it ideal for a range of tasks such as metal forging, hardening, and pre-heating for welding. The system is built for continuous operation and provides precise control to ensure optimal heating efficiency and safety.