Across International

Ai ETL C1D1 Dual-Jacketed 300L 316L-Grade SST Reactor

Ai ETL C1D1 Dual-Jacketed 300L 316L-Grade SST Reactor

No reviews

SKU: SR300

- Regular price

- Price: $31,990.00

- Regular price

- List Price: $37,635.29

- Sale price

- Price: $31,990.00

- Unit price

- / per

:

You Save:

$5,645.29 (15%)

Sale

Sold out

Couldn't load pickup availability

In stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

The Ai 300L Dual-Jacketed 316L Stainless Steel Reactor is an advanced, high-capacity processing unit designed for demanding applications in industries such as pharmaceuticals, food, and chemicals. Featuring a dual-jacketed design, ElectroPolished internal surfaces, and a robust shell and tube heat exchanger, this reactor ensures efficient and reliable processing of volatile or temperature-sensitive materials. The C1D1 peer review option and ETL certification make it suitable for hazardous environments and industries that require strict safety and performance standards.

Key Features:

- Horizontally Mounted Condenser: The horizontally mounted condenser reduces the center of gravity, ensuring enhanced stability during operation.

- Dual-Jacketed Design: This reactor features a dual-jacketed system with a sealed outer insulation jacket for superior temperature control, helping to maintain optimal process conditions within the chamber.

- 316L Stainless Steel Construction: All wetted parts are made from pharmaceutical-grade 316L stainless steel, providing corrosion resistance and ensuring high purity in sensitive applications.

- Shell and Tube Heat Exchanger: Equipped with a 110-tube shell and tube heat exchanger for efficient condensation, maximizing heat transfer.

- ElectroPolished Interior: The internal chamber is ElectroPolished, which reduces surface roughness, improves vacuum pressures, out-gassing rates, and prolongs equipment lifespan by minimizing friction and wear.

- Detachable Condenser and Collection Tanks: Dual collection tanks with large sight glasses allow for easy draining without breaking the vacuum. The condenser can also be detached for cleaning and maintenance.

- Space-Saving Integrated Stirring Motor Controller: The reactor includes a compact, integrated motor controller that eliminates messy cables and saves space.

- Heavy-Duty Frame: The reactor is mounted on a stainless steel frame with swivel casters, making it easy to move and position in different work environments.

- Comprehensive Port Configuration: The reactor features large ports (12" at the top, 6" at the bottom) for easy chamber cleaning, with ports for vacuum, recirculating fluid, and drainage.

- Comprehensive Lubrication Requirements: The pneumatic stirring motor requires specific lubrication (e.g., Mobil Grease XHP 222 for motor lubrication and Shell Vitrea Oil 32 for air lubrication) to ensure smooth, safe operation.

Specifications:

- Model: SR300

-

Electric Stirring Motor:

- Power: 220V, 50/60Hz, 1~Phase, 200W (1/4 HP)

- Rotation Speed: 450 rpm max. (±8%)

- Starting Torque: 3.0 N·m

- Rated Torque: 1.54 N·m

- Gearbox Ratio: 3:1 to 180:1

- Controller: Delta, UL Listed

-

Pneumatic Stirring Motor (optional):

- Power: 1/4 HP

- Rotation: 450 rpm max.

- Compressed Air Pressure: 30 to 80 psi

- Lubrication: Mobil Grease XHP 222, Shell Vitrea Oil 32

- Safety: Detach air supply when not in use and ensure the exhaust port is clear of debris.

-

Port Configuration:

- Lid: 12" TriClamp

- Center Motor Port: 3" TriClamp

- Drain Port: 6" TriClamp

- Drain Port On/Off Valve: 2" TriClamp

- Vacuum Port: 1.5" TriClamp

- Condenser Recirculating Fluid Port: 1/2" Female NPT

- Vessel Jacket Recirculating Fluid Port: 1" Female NPT

-

Main Vessel:

- Volume: 300L

- Material: 316L Grade Stainless Steel

- Interior Finish: ElectroPolished

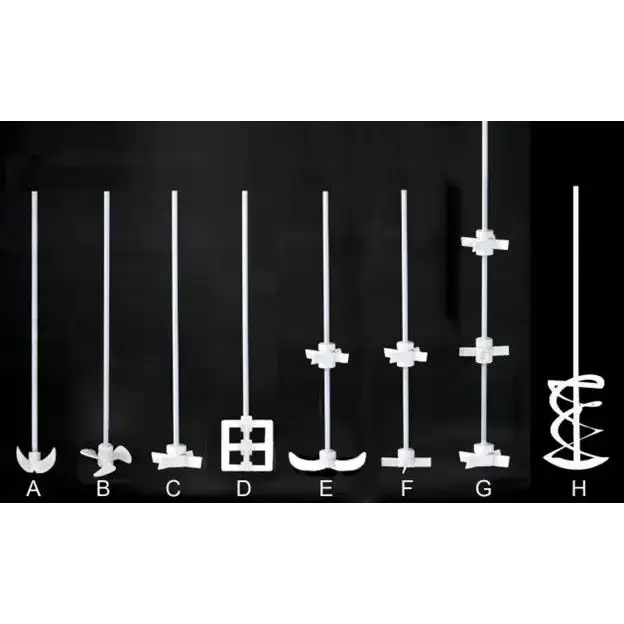

- Agitator: Propeller, 3-Blade, Dual-Layer, 316L Stainless Steel

-

Collection Tanks:

- Option 1: 20L x 2, 316L Stainless Steel with Manifold

- Option 2: 50L x 1, 304 Stainless Steel with Dolly

- Option 3: 100L x 1, 304 Stainless Steel with Dolly

-

Main Condenser:

- Style: Shell and Tube Heat Exchanger

- Number of Tubes: 110

- Condensing Area: 1 m²

- Ultimate Vacuum Level: 1 Torr

- Temperature Range: -55°C to +250°C (-67°F to +482°F)

- Temperature Sensor/Display: Regular and Explosion-Proof models available

- Sealing Gasket: Food-grade Viton

- Main Mounting Frame: Heavy-duty 304-grade stainless steel, mounted on four casters

- Drain Port Ground Clearance: 19.5"

- Shipping Weight: 770 lbs (Unit), 990 lbs (Shipping)

- Shipping Dimensions: 48" x 38" x 88"

-

Assembled Dimensions:

- Without Receiving Flasks: 38" x 47" x 81"

- With 20L Receiving Flasks: 51" x 47" x 81"

Compliance and Certifications:

- ETL Certified: Meets UL and CSA standards.

- C1D1 Peer Review by PSI (optional): Approved for use in environments with hazardous chemicals, such as acetone, ethanol, heptane, isopropyl alcohol, and others.