Across International

Glass Reactor Ai 20L Single or Dual Jacketed Systems

Glass Reactor Ai 20L Single or Dual Jacketed Systems

SKU: R20

- Regular price

- Price: $6,490.00

- Regular price

- List Price: $7,635.29

- Sale price

- Price: $6,490.00

- Unit price

- / per

Couldn't load pickup availability

1000 in stock

Share

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

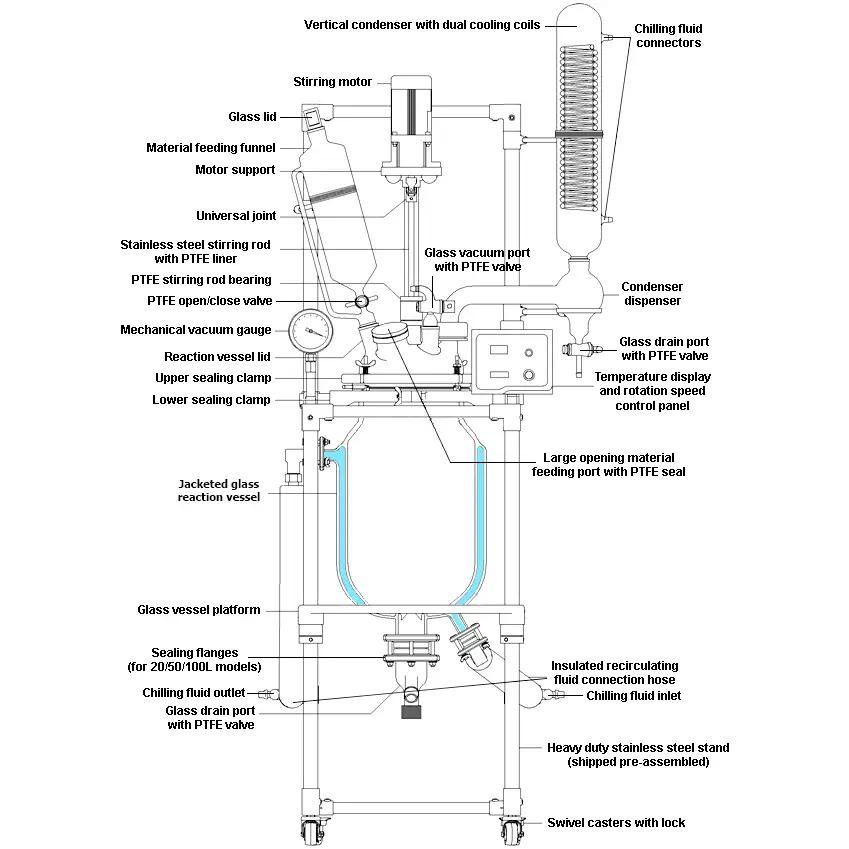

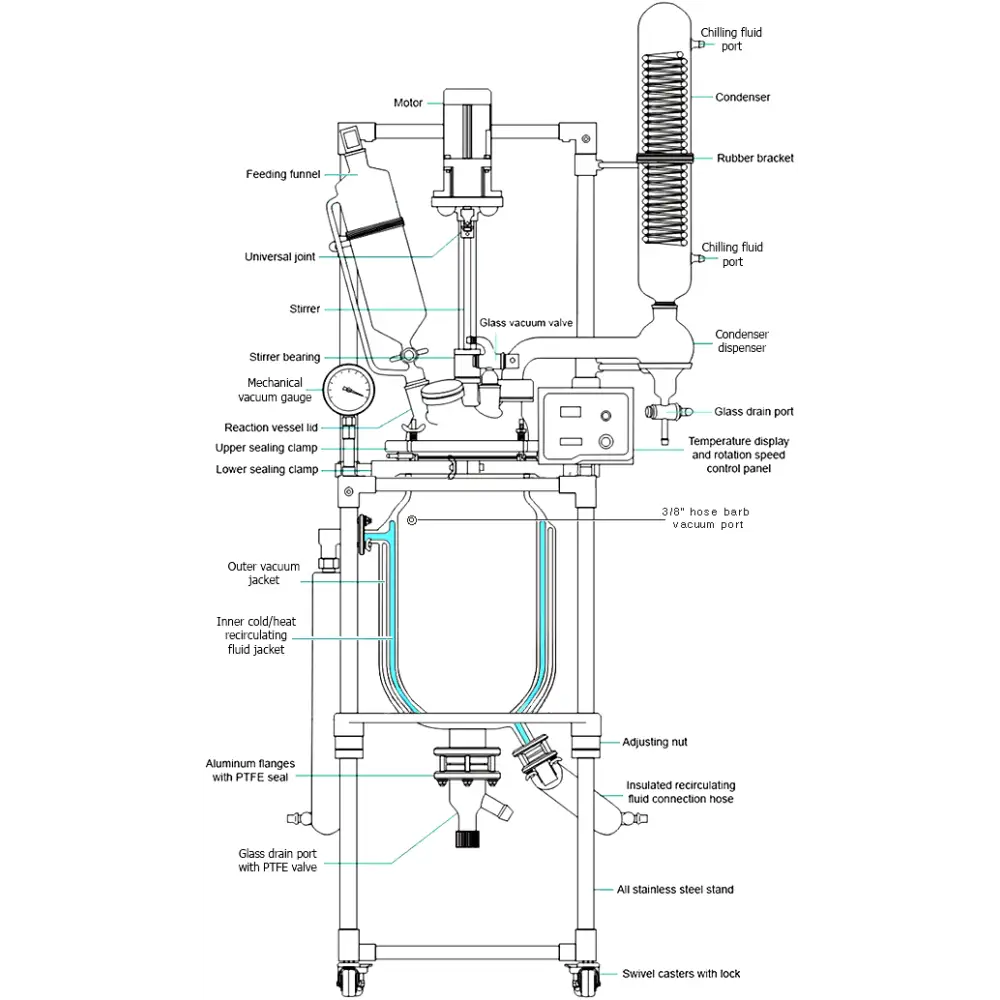

The Ai 20L Single or Dual Jacketed Glass Reactor from the Ai R-series is a high-performance reaction vessel designed for synthetic processes that require precise temperature control and vacuum environments. This reactor is ideal for applications involving materials that need to be reacted under controlled conditions, offering adjustable stirring speeds and precise material feeding with a constant pressure funnel. The built-in condenser allows for efficient recovery of materials at controlled rates.

Key Features:

-

ETL Tested: The reactor is ETL certified to UL and CSA standards, ensuring high performance and safety. CE certification is also available.

-

Free High-Quality Insulation Jacket: Comes with a free thermo insulation jacket (a $459 value) designed to extend chiller life, improve temperature control, and lower utility costs. This jacket features an open/close viewing window and adjustable drawstrings for easy installation.

-

Dual Jacketed Option: The dual-jacketed model provides the added benefit of drawing a vacuum from the outer jacket, ensuring better temperature control of the recirculating fluid and preventing frost formation on the vessel's exterior.

-

Durable Construction: All sealing components are made from solvent-resistant PTFE, ensuring long-term durability and reliability. The glass vessel is made from high borosilicate glass 3.3, known for its resistance to heat, cold, and chemical corrosion.

-

Adjustable Stirring: The reactor offers adjustable stirring speeds from 50 to 500 rpm, allowing for high torque or high-speed operation, depending on the needs of your reaction.

-

PTFE Stirring Rod Bearing: Patented bearing design provides reliable and quiet stirring.

-

Multi-Layer Stirring Blades: Optional blades are available for optimal reaction efficiency, especially when dealing with viscous materials.

-

Wide Temperature Range: The reactor can operate in temperatures from -110°F to 400°F, making it suitable for a variety of processes.

-

Efficient Condenser: A large condenser cooling surface ensures exceptional condensation performance, making it ideal for processes that require material recovery.

-

Heavy Duty Supporting Framework: The stainless steel reinforced framework with lockable casters ensures mobility and stability. The glass vessel and support frame are shipped pre-assembled for easy setup.

-

Safety: The reactor features various safety mechanisms to prevent accidents, including over-current protection and vacuum safeguards. Users should take caution when operating to avoid entanglement with rotating parts and the risks associated with working with air-reactive materials under vacuum.

-

One Year Warranty: Includes a one-year warranty, and lifetime US-based parts, service, and support for peace of mind.

Specifications:

| Model | R10 | R20 | R50 | R100 |

|---|---|---|---|---|

| Electrical Requirements | 110V 60Hz or 220V 50/60Hz | 110V 60Hz or 220V 50/60Hz | 110V 60Hz or 220V 50/60Hz | 110V 60Hz or 220V 50/60Hz |

| Power | 90W | 140W | 250W | 250W |

| Reaction Vessel Capacity | 2.6 gallons (10L) | 5.3 gallons (20L) | 13 gallons (50L) | 26 gallons (100L) |

| Cooling/Heating Jacket Capacity | 0.8 gallons (3L) | 1.6 gallons (6L) | 4.2 gallons (16L) | 8 gallons (30L) |

| Glass Material | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 | High borosilicate glass 3.3 |

| Rotation Controller | Digital controller with variable frequency drive | Digital controller with variable frequency drive | Digital controller with variable frequency drive | Digital controller with variable frequency drive |

| Rotation Speed | 50 to 500 rpm | 50 to 500 rpm | 50 to 500 rpm | 50 to 500 rpm |

| Maximum Jacket Pressure | 4.4 psi (0.03 MPa) | 4.4 psi (0.03 MPa) | 4.4 psi (0.03 MPa) | 4.4 psi (0.03 MPa) |

| Drain Valve | Flush seal design | Flush seal design | Flush seal design | Flush seal design |

| Agitator | Impeller, PTFE lined | Impeller, PTFE lined | Impeller, PTFE lined | Impeller, PTFE lined |

| Funnel | Pressure equalizing | Pressure equalizing | Pressure equalizing | Pressure equalizing |

| Vacuum Gauge | Mechanical | Mechanical | Mechanical | Mechanical |

| Glass Vessel Temperature Range | -110°F to 400°F | -110°F to 400°F | -110°F to 400°F | -110°F to 400°F |

| Vacuum Level | 20 torr | 20 torr | 20 torr | 20 torr |

| Vacuum Sealing | Glass and PTFE | Glass and PTFE | Glass and PTFE | Glass and PTFE |

| Drain Port Ground Clearance | 15 inches | 13 inches | 12.5 inches | 13.5 inches |

| Unit Dimensions (WxDxH) | 18 x 26 x 78 inches | 20 x 27 x 80 inches | 26 x 33 x 85 inches | 28 x 42 x 95 inches |

| Shipping Dimensions | 24 x 67 x 26 inches | 24 x 75 x 31 inches | 25 x 83 x 42 inches | 26 x 88 x 45 inches |

| Shipping Weight | 240 lbs | 262 lbs | 330 lbs | 390 lbs |

| Compliance | ETL listed to UL & CSA (optional), CE (optional) | ETL listed to UL & CSA (optional), CE (optional) | ETL listed to UL & CSA (optional), CE (optional) | ETL listed to UL & CSA (optional), CE (optional) |